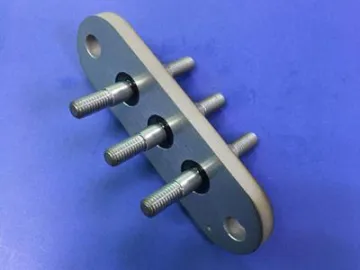

Electrical Power Feedthrough

Application:

This electrical power feedthrough feedthrough mainly used in high power equipment that requires hermeticity, electrical insulation and high pressure withstanding while establishing electrical connections.

Materials:

Body: C45#

Pin:C45#

Glass: Elan 48#

Surface treatment:

We adopt the environmental friendly electroplating technique, which is electroless nickel plating at 3-5 μm thickness. The nickel coat does not contain hazardous substances such as mercury, lead, cadmium and hexavalent chromium, reaching EU's standards. It passed the SGS environmental test.

Index

glass to metal seal, hermetic seals

Scan QR to Read

Links:https://globefindpro.com/products/30388.html

Links:https://globefindpro.com/products/30388.html

Recommended Products

-

Semi-hermetic Commercial Air Conditioner Terminal Plate

Semi-hermetic Commercial Air Conditioner Terminal Plate

-

Z Series LED Downlight, SMD Slimline LED Downlight

Z Series LED Downlight, SMD Slimline LED Downlight

-

BLK100kg Lyophilization Equipment Freeze Dryer

BLK100kg Lyophilization Equipment Freeze Dryer

-

Hermetic 12V-24V Car Air Conditioner Compressor Terminal

Hermetic 12V-24V Car Air Conditioner Compressor Terminal

-

Ultra Thin Recessed LED Panel Light

Ultra Thin Recessed LED Panel Light

-

Hermetic 72V-810V Auto Air Conditioner Compressor Terminal

Hermetic 72V-810V Auto Air Conditioner Compressor Terminal

-

Hermetic Home Air Conditioner Terminal, Fridge Compressor Terminal

Hermetic Home Air Conditioner Terminal, Fridge Compressor Terminal

-

Dimmable LED Panel Light

Dimmable LED Panel Light

-

24W Recessed LED Light Panel

24W Recessed LED Light Panel

-

Sight Glass

Sight Glass

-

Mini Compressor Seal Cap

Mini Compressor Seal Cap

-

UGR

UGR

Hot Products