TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

TYFZ16 construction wall panel production plant is applicable for batch production of lightweight compound wall panel with calcium silicate board on its both sides. Applicable materials include cement, fly ash, EPS polyphenyl granule, sand, ceramsite, etc. It can produce 40 pieces of wall panels per batch.

The system adopts hydraulic open/closed molding, which avoids potention risks that often exists in manual open/closed molding for traditional vertical type. Moreover, it realizes high automation of whole line running, which greatly improves working efficiency.

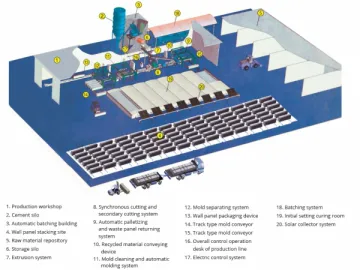

Main system consists of batching mixing system, precast wall panel system, hydraulic whole open molding system, hydraulic rotating system, whole wall panel ejecting, rotating and stacking system, precast wall panel automatic cycling system, frequency conversion shuttle system, numerical control power distribution system.

| Output per batch | Thickness | Width | Length |

| 40 | 75mm | 610mm | 2440mm/3000mm |

| 40 | 90mm | ||

| 32 | 120mm | ||

| 26 | 150mm |

Note: The dimensions above are normal dimensions. Tianyi also provides customized production line to meet your special needs for wall panel.

Main Equipment:(1) TYF01 Vertical Precast Wall Panel Machine

TYF01 vertical precast wall panel machine is equipped with automatic moving conversion system. It has advantages of simpler and faster operation, and large output. It can produce 40 pieces of wall panels per batch.

(2) Weighing System

Weighing system can automatically weigh cement and other materials with great accuracy and easy operation.

(3) Mixing System

Large-scale fixed mixing equipment can give a more uniformed mixing slurry and higher slip casting effciency.

(4) Mobile Slip Casting System

Pumping pipes are sealed and equipped with two-station slip casting guns. It has advantages of fast slip casting and high degree of density.

(5) Wall Panel Ejecting and Stacking System

Wall panel ejecting and stacking system proceeds whole wall panel ejecting and stacking to finished products. Compared to traditional manual wall panel ejecting methods, it reduces the rate of spoiled products and improves capacity.

| Outline size | 3590L×1470W×3450H mm |

| Vibrating system power | 1.5 kW |

| Structure | Host, vibrating system, forming stripe |

| Cement gauge box | 1000kg |

| Pneumatic butterfly valve | DN300 |

| Flexible adapter sleev | DN300 |

| Pressure sensor | 1000kg |

| Vibrator | Pneumatic |

| Mixing platform | 4300*3850mm |

| Landing leg | 4300*3500mm |

| Steel ladder | 14# U-bar |

| Mixer volume | 3m³ |

| Mixer power | 30kW |

| Lifting hopper volume | 1m³ |

| Lifting hopper power | 4.5kW |

Close

| Pumping Pressure in Theory | High pressure | 0.5 Mpa |

| Low pressure | 0.4 Mpa | |

| Transport Capacity in Theory | High pressure | 5 Mpa |

| Low pressure | 9.4 Mpa | |

| Max. Transport Distance | Horizontal | 300 mm |

| Vertical | 120 mm | |

| Main Motor Power | 7.5 kW | |

| Hopper Volume | 3m³ | |

| Loading Height | 1000 mm | |

| Hydraulic Oil Tank Volume | 60 L | |

| Distribution Valve Form | Ball valve | |

| Main Machine Weight | 500kg | |

| Frame Size: L×W×H | 1785×960×1700mm | |

| Hydraulic power | 4kw |

| Wall panel ejecting power | 5.5kw |

| Moving power | 1.5kw |

Index

construction partition wall, precast wall panel, wall production line, interior wall machines

Links:https://globefindpro.com/products/30477.html

-

Vertical Precast Wall Panel Machine

Vertical Precast Wall Panel Machine

-

TY08 Prestressed Wall Panel Machine

TY08 Prestressed Wall Panel Machine

-

Automated Center Pushing Conveyor

Automated Center Pushing Conveyor

-

TY11 Prestressed Wall Panel Machine

TY11 Prestressed Wall Panel Machine

-

Automatic Paint Spraying Line

Automatic Paint Spraying Line

-

TY06 Prestressed Wall Panel Machine

TY06 Prestressed Wall Panel Machine

-

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

-

Precast Concrete Production Line

Precast Concrete Production Line

-

TY03A/TY03B Precast Wall Panel Machine

TY03A/TY03B Precast Wall Panel Machine

-

TYF13 Prestressed Wall Panel Machine

TYF13 Prestressed Wall Panel Machine

-

TYJ16 Construction Extruded Wall Panel Production Plant

TYJ16 Construction Extruded Wall Panel Production Plant

-

Paint Leveling Drying Tunnel

Paint Leveling Drying Tunnel