Application

The K series extrusion blow molding machine produced by Timey was developed for the production of plastic containers made from various materials, such as PE, PP, and EVA for the packaging of foods, medicines, detergents, chemicals, and oils.

Parameter

Single Layer Film Extrusion Blow Molding Machine | Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-01 | Single layer | 0.5 | PE,PP,PS | 4 | 65,70,75 | 4000 | 3.1X1.9X2.1 | 130 | 200 | 55 | 11 | 32 | 32 |

| Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-01-1 | Single layer | 5 | PE,PP,PS,PC,PVC | 1 | / | 4600 | 3.4x2.1x2.2 | 200 | 250 | 65 | 15 | 60 | 60 |

| Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-01-2 | Single layer | 10 | PE,PP,PS,PC,PV | 1 | / | 6300 | 3.9x2.3x2.5 | 230 | 350 | 75 | 22/30 | 95/105 | 54.5/62.5 |

Double Layer Film Extrusion Blow Molding Machine | Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-04-1 | Double layers | 1 | PE/PP | 4 | 85,100 | 7000 | 3.9x2.2x2.5 | 230 | 300 | 55/75 | 22(30) / 11 | 90(100) / 30 | 71.7/80.7 |

| Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-04-2 | Double layers | 5 | PE/PP | 1 | / | 4400 | 3.4x2.1x2.2 | 200 | 250 | 65/25 | 15 / 2.2 | 60 / 2 | 42.2 |

| Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-04-3 | Double layers | 10 | PE/PP | 1 | / | 7000 | 3.9x2.2x2.5 | 230 | 300 | 75/55 | 11/22 | 90 / 30 | 73.2 |

Extrusion Blow Molding Machine with Liquid Level Line | Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-05-1 | Single layer with liquid level line | 5 | PE | 1 | / | 7000 | 3.5X2.3X2.4 | 200 | 200 | 75 / 25 | 22(30) / 2.2 | 90(105) / 2 | 73.3 / 82.7 |

| Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-05-2 | Single layer with liquid level line | 5 | PE | 1 | / | 4600 | 3.4x2.1x2.2 | 200 | 250 | 65 / 25 | 15 / 2.2 | 60 / 2 | 42.2 |

| Model | Category | Max Volume(L) | Material | Die Head No. | Center Distance (mm) | Net Weight(Kg) | Machine Dimension(l x w x h) | Min Clamping Distance of Mould(mm) | Clamping stroke(mm) | Extruder diameter(mm) | Extruder Motor Power(kW) | Max extrusion capacity (Kg/h) | Total power (kW) |

| TMK-06-1 | Double layers with liquid level line | 5 | PE | 1 | / | 4600 | 3.4x2.1x2.2 | 200 | 250 | 65 /45 / 25 | 15 / 5.5 /2.2 | 60 / 14 / 2 | 53.8 |

Features

1. The molding machine features three different operating modes: manual, semi-automatic, and automatic.

2. The machine uses Festo and SMC pneumatic, hyrdraulic, and electrical control components in order to ensure a long useful life for the equipment.

3. K series extrusion blow molding machines feature fine processing technology with a smooth flow channels and no dead angles within. This guarantees the grinding head will not fill up with undesired materials.

4. We optimized the design of the hydraulic oil conveying pipes, making it convenient for users to adjust the parameters with a simple change of settings on the control panel. This results in higher accuracy operation with added efficiency.

5. The motor of the molding machine features a frequency conversion adjustable speed extruder motor. This allows for adaptability for the requirements of the variable screw speed during the blow molding process.

We offer plastic machines for manufacturing plastic bottles and containers. Our K series extrusion blow molding machine is suitable for making polyethylene water bottles, polypropylene containers, PS containers, polycarbonate bottles, PVC bottles, EVA containers, etc. We have all the production resources to make plastic blow molding machines with custom made service, offering quality machines for making plastic food containers, cooking oil containers, medical containers, detergent bottles, chemical containers.

600KN Bottle Blowing Machine

600KN Bottle Blowing Machine

Shoe Last 3D Scanner

Shoe Last 3D Scanner

Automatic Screen Printing Labeling Machine

Automatic Screen Printing Labeling Machine

E Series Extrusion Blow Molding Machine

E Series Extrusion Blow Molding Machine

Corrugated Box Slotter

Corrugated Box Slotter

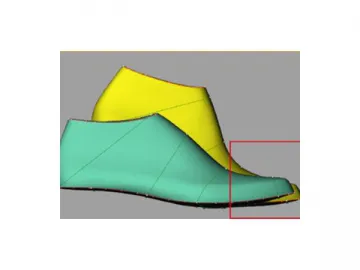

Shoe Last Machine Designing Software

Shoe Last Machine Designing Software

Shoe Last Cutter Grinding Machine

Shoe Last Cutter Grinding Machine

Hot Runner Plastic Mold Manufacturing

Hot Runner Plastic Mold Manufacturing

W200IV W400IV Metal Mold Repair Laser Welder

W200IV W400IV Metal Mold Repair Laser Welder

Die Cutter

Die Cutter

G5 Corrugated Board Converting Machine

G5 Corrugated Board Converting Machine

W220III W400III Metal Mold Repair Laser Welder

W220III W400III Metal Mold Repair Laser Welder