Functionally Graded Carbide

Conventional Tungsten Carbide / Wear Resistant Tungsten Carbide / Cemented Tungsten Carbide

The HeavyStone Surface™

Here at the JIMS, we have partnered with HeavyStone Lab LLC to manufacture functionally graded carbide compacts, produced using HeavyStone Lab LLC’s patented technology. This process for manufacturing functionally graded cemented tungsten carbide turns conventional tungsten carbide into the HeavyStone Surface™ functionally graded carbide with a wear resistant surface and a tough to break core structure. This surface has been found to offer an outstanding combination of wear resistance and fracture toughness, and thus, a better engineering performance with field tests showing results of a 30% increase in footage drilled. HeavyStone Surface™ carbides produced by the JIMS have been widely used in China, the U.S, Korea, Brazil and Europe.

Technical Parameters

| Grade | Co (%) | Density | Hardness | TRS(N/mm2) | Recommended use |

| GM06 | 6 | 14.95 | 90.3 | 2800 | DTH hammer, medium to hard rock |

| KM65 | 6.5 | 14.9 | 90 | 3000 | |

| GM08 | 8 | 14.8 | 88.7 | 3200 | |

| J510 | 10 | 14.55 | 88.1 | 3300 | Roller cone drill bit |

| J411 | 11 | 14.45 | 88.8 | 3200 | |

| J512 | 12 | 14.35 | 87.3 | 3200 | |

| JCK1 | 10 | 14.5 | 85.7 | 2400 | Road milling, mining |

| JCK3-S | 6.5 | 14.85 | 87.5 | 2200 | |

| YH13 | 13 | 14.25 | 88.7 | 3500 | PDC Substrate |

| YH16 | 16 | 13.9 | 86.6 | 3200 |

Links:https://globefindpro.com/products/35447.html

-

Tungsten Carbide Rods and Strips

Tungsten Carbide Rods and Strips

-

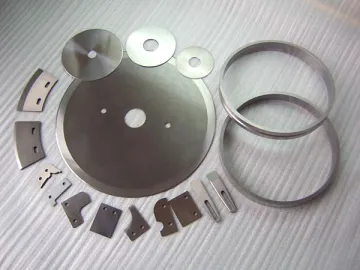

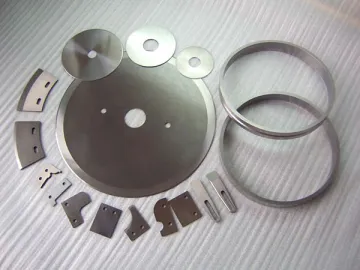

Special Cemented Carbide Products

Special Cemented Carbide Products

-

Low Row

Low Row

-

Q Switched Nd Yag Laser

Q Switched Nd Yag Laser

-

980nm Diode Laser Vascular Removal Machine

980nm Diode Laser Vascular Removal Machine

-

Shoulder Press

Shoulder Press

-

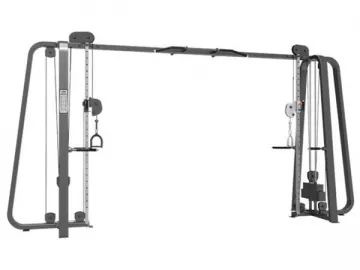

Adjustable Cable Crossover

Adjustable Cable Crossover

-

CO2 Fractional laser machine

CO2 Fractional laser machine

-

Carbide Burr Blanks (for Woodworking)

Carbide Burr Blanks (for Woodworking)

-

Kuma Shape Body Slimming Machine

Kuma Shape Body Slimming Machine

-

Mini Tattoo Removal Laser

Mini Tattoo Removal Laser

-

LED Light Therapy Machine

LED Light Therapy Machine