Manual Fed Hot Stamping and Die Cutting Machine

This machine is suitable for thermo printing hot-stamp foil onto various paper products, and also can be used as cutting machine for mold cutting and creasing various cardboard boxes and cases. Various high-grade exquisite printed products can be thermo-printed concavely and convexly on this machine so as to get stereoscopic, exquisite and beautiful packed and decorated products.

| Model | TYMQ1100 | TYMQ930 | TYMQ750 |

| Plan metric effective area | 1100×800 | 930×670 | 750×500 |

| Total electro thermal power | 9(kw) | 9(kw) | 4.5(kw) |

| Thermoregulation range | 1-399℃ | 1-399℃ | 1-399℃ |

| Continuous thermo printing speed | 20(Storks/min) | 22(Storks/min) | 25(Storks/min) |

| Volume of common foil-feeding | 1-800mm | 1-600mm | 1-500mm |

| Leapfrog frequency | 1-99 | 1-99 | 1-99 |

| Foil-feeding resolute | 1mm | 1mm | 1mm |

| Motor dates | 4(kw)/6(Series) | 4(kw)/4(Series) | 2.2(kw)/6(Series) |

| Overall Dimension | 1900×2000×1900mm | 1500×1700×1620mm | 1300×1300×1700mm |

| Net weight | 4700kg | 3100kg | 1800kg |

Scan QR to Read

Links:https://globefindpro.com/products/35795.html

Links:https://globefindpro.com/products/35795.html

Recommended Products

-

Automatic Paper Cup Forming Machine, JBZ

Automatic Paper Cup Forming Machine, JBZ

-

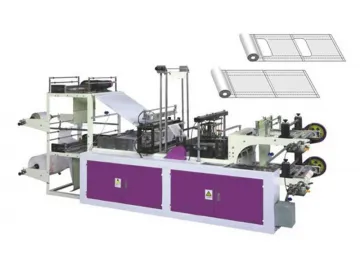

Plastic Roll Bag Making Machine (Microcomputer Controlled High Speed), GJHD

Plastic Roll Bag Making Machine (Microcomputer Controlled High Speed), GJHD

-

Automatic UV Coating Machine, SGZ-III-1200

Automatic UV Coating Machine, SGZ-III-1200

-

Paper Bag Forming Machine (Sheet Feeding), ZB1100A

Paper Bag Forming Machine (Sheet Feeding), ZB1100A

-

Spot UV Varnishing Machine, SGZJ1200

Spot UV Varnishing Machine, SGZJ1200

-

Automatic Pre-fold and Lock Bottom Folder Gluer, SHH800AG

Automatic Pre-fold and Lock Bottom Folder Gluer, SHH800AG

-

Carton Box Erecting Machine (Lunch Box Forming Machine)

Carton Box Erecting Machine (Lunch Box Forming Machine)

-

Paper Bag Making Machine (Sheet Feeding), ZB960C-330

Paper Bag Making Machine (Sheet Feeding), ZB960C-330

-

FM-E Automatic Vertical Laminating Machine

FM-E Automatic Vertical Laminating Machine

-

FM1050D Automatic Thermo Film Laminating Machine

FM1050D Automatic Thermo Film Laminating Machine

-

FY1050B Automatic Thermal Film Laminating Machine

FY1050B Automatic Thermal Film Laminating Machine

-

Hydraulic Thermal Laminator (with Slitting) QLFM-Y

Hydraulic Thermal Laminator (with Slitting) QLFM-Y

Hot Products