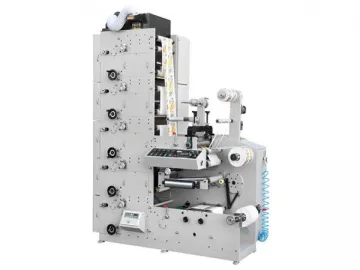

Label Flexographic Printing Machine, ZBS320 (Flexo Printer)

This flexographic printing machine is widely used in adhesive label printing and also plastic sleeve label printing.

| Model | ZBS-320 | ZBS-320G |

| Printing speed: | 50m/min | 55m/min |

| Printing colour : | 5colours | 5colours |

| Max. web width : | 320mm | 320mm |

| Max. printing width: | 310mm | 310mm |

| Max. unwinding diameter: | 600mm | 650mm |

| Max. rewinding diameter: | 600mm | 650mm |

| Printing perimeter: | 175-355mm | 175-355mm |

| Precision of chromatography: | ±0.1mm | ±0.1mm |

| Dimensions: | 2(L)x1.1(W)x2.6(H)(m) | 2.6(L)x1.1(W)x2.6(H)(m) |

| Machine weight: | about 2200kg | about 3100kg |

Scan QR to Read

Links:https://globefindpro.com/products/35874.html

Links:https://globefindpro.com/products/35874.html

Recommended Products

-

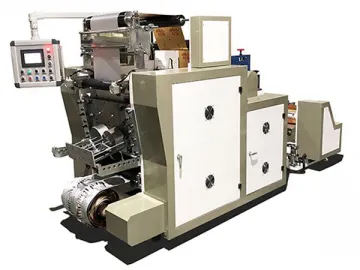

High Speed Automatic Envelope Making Machine, 328LD

High Speed Automatic Envelope Making Machine, 328LD

-

Anilox Roller Washing Machine, QXJ-450

Anilox Roller Washing Machine, QXJ-450

-

Automatic Carton Refraction Embossing Machine

Automatic Carton Refraction Embossing Machine

-

High Precision Aluminum Lids Die Cut Punching Machine (IML Puncher) MQGB-B

High Precision Aluminum Lids Die Cut Punching Machine (IML Puncher) MQGB-B

-

Flexo Plate Making Machine

Flexo Plate Making Machine

-

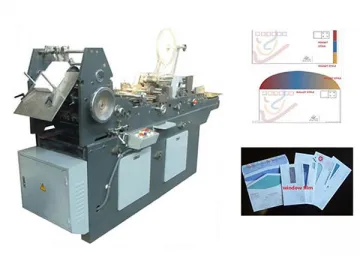

Automatic Flap Gluing Envelope (Pocket) Making Machine ZF128A

Automatic Flap Gluing Envelope (Pocket) Making Machine ZF128A

-

Economic Automatic Slitting Machine, FQL

Economic Automatic Slitting Machine, FQL

-

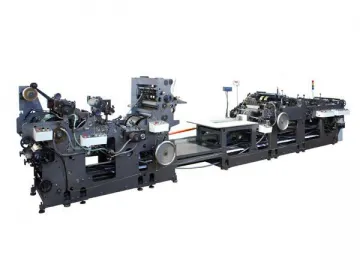

High Speed Gluing Center-Seal and Gusset Machine

High Speed Gluing Center-Seal and Gusset Machine

-

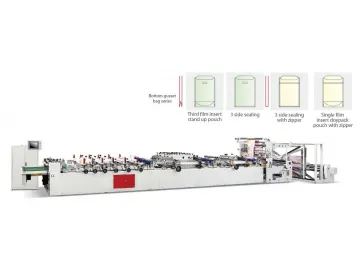

Pouch Bag Making Machine, 600C FD

Pouch Bag Making Machine, 600C FD

-

PLC Control High Speed Automatic Slitting Machine, FQL

PLC Control High Speed Automatic Slitting Machine, FQL

-

High Speed Dry Type Laminator, GF-A

High Speed Dry Type Laminator, GF-A

-

Flower Sleeve Bag Making Machine, DRQ-F

Flower Sleeve Bag Making Machine, DRQ-F

Hot Products