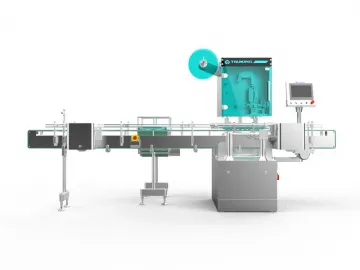

Rotary Capping Machine, SC-R250

The SC-R250 rotary capping machine is designed to automatically feed, sort and apply screw caps to various containers, including round bottles, square bottles and oval bottles. It is an ideal bottle capper machine for use in pharmaceutical, supplement, candy and household chemical, food and beverage industries.

Tool-less changeovers for timing screws, star wheels and capping heads, locating pin for precise positioning, less than 30 minutes for changeover;

Detection of upside down bottles, protection against overload to the screw;

Pneumatic three-jaw gripper, automatic centering without damaging caps;

Exclusive permanent magnet clutch torque limiter, torque adjustment and precise control of cap torque;

Motorized height adjustment to accommodate various bottle sizes;

Detection and rejection of upside down caps, caps with no aluminum foil, loosen caps and deformed caps;

Transparent tempered glass door, stainless steel and aluminum construction, ensuring operation safety and easy cleaning;

Human-machine operation system with 10-inch screen; Technical Specifications

| Overall dimensions | 1250mm (L)×1350mm (W)×2250mm(H) (main machine) | |

| Weight | 1600kg | |

| Max. capacity | 250 bottles/min | |

| Applicable specification | Bottle height: 45-200mm | |

| Bottle diameter: 020-100mm | ||

| Cap height: 10-30mm | ||

| Cap diameter: 020-60mm | ||

| Number of capping head | 10 | |

| Unscrambling speed | Max. 350 caps/min. | |

| Detection and rejection | Removal of misaligned cap and caps with no aluminum foil (standard) Removal of upside down aluminum foil (optional) | |

| Breakage rate | ||

| Screw-on cap pass rate | ≥99.98% | |

| Noise level | ≤70dB | |

| Electric and air requirements | Main Power Supply | AC220V-50HZ-3 wire |

| Installed capacity | 3.0kW | |

| Compressed air | Quick change adapter: 10mm 200L/min(0.6MPa-0.8MPa) | |

equipment for pharmacy packing

screw-on capping machine

freestanding capping machine

Scan QR to Read

Links:https://globefindpro.com/products/3652.html

Links:https://globefindpro.com/products/3652.html

Recommended Products

-

Conical Mill with Vacuum Conveying, TQZ Series

Conical Mill with Vacuum Conveying, TQZ Series

-

GH018-F Automatic High Speed Spool Sewing Thread Winding Machine

GH018-F Automatic High Speed Spool Sewing Thread Winding Machine

-

Binder Tank, SYC Series

Binder Tank, SYC Series

-

Pharmaceutical Counting and Bottle Filling Machine, CFM-04

Pharmaceutical Counting and Bottle Filling Machine, CFM-04

-

GH019-SA Semi-automatic Sewing Thread Winding Machine

GH019-SA Semi-automatic Sewing Thread Winding Machine

-

Desiccant Inserter (200 bottles/min), ISD-200

Desiccant Inserter (200 bottles/min), ISD-200

-

Pharmaceutical Bin Washer, QD Series

Pharmaceutical Bin Washer, QD Series

-

Stick Packing and Weighing Machine, SP-W12

Stick Packing and Weighing Machine, SP-W12

-

IBC Bin for Transfer, ZLDF Series

IBC Bin for Transfer, ZLDF Series

-

Stainless Steel Flexible Coupling, Model 96MP

Stainless Steel Flexible Coupling, Model 96MP

-

GH018-B High-Speed Yarn Cone To Cone Rewinder Machine

GH018-B High-Speed Yarn Cone To Cone Rewinder Machine

-

GH018-Z High-Speed Yarn Oiled Special Winding Machine

GH018-Z High-Speed Yarn Oiled Special Winding Machine

Hot Products