Cement Production Line

CementProduction Line

The cementproduction line is composed of a great variety of equipment,including rotary kiln, sintering furnace, ball mill, cement mill,dryer, granulating machine, crushing machine, dust collector, platefeeder, humidifying tower, bucket elevator, screw conveyor, as wellas many other types of machines for material crushing, conveying,stacking and taking, weighting, heating, cooling, classification,drying, as well as packaging during the cement production process. Inaddition to cementmanufacturingequipmentwith production capacity of 6000 t/d, 5000 t/d, and 2500 t/d, we canalso offer EPC contractor service. Following is a detaileddescription of the production process of the production line.

RawMaterial Preparation

1. Limestone crushing, conveying andstorage

The cementproduction equipmentincorporates a crushing machine supporting limestone crushing inoutdoor environment. The crushed materials are delivered via a beltconveyor to a round storage yard for pre-homogenization and temporarystorage. A cantilever material piling machine and a bridge-typematerial taking machine are available for handling the crushedlimestone materials in the storage yard. After homogenization, thematerials are delivered to the raw material batching station via arubber belt conveyor.

2. Auxiliary material storage, crushing,and conveying

The auxiliary raw materials, such as the sandstoneand iron ore, should be prepared, and readily accessible in anoutdoor storage yard. The sandstone should be crushed by hammercrushers. The crushed sandstone and iron ore are then transferred tocorresponding storage silos in the raw material batching station.Other auxiliary raw materials, like the coal ash, can beautomatically unloaded from trucks, and then conveyed to the coal ashstorage silo in the raw material batching station via a specializedpipeline system.

Cement Production Flow

1. Raw materialbatching station

The station includes four storage silos for theprepared limestone, sandstone, iron ore, and coal ash respectively. Aweigh feeder is available at the bottom of each storage silo, andacts to feed the different raw materials in accordance with presetproportions. It can also be used in combination with rubber beltconveyor to send the raw materials into vertical grinders.

2.Raw material grinding and waste gas treatment

The cementproductionplantadopts the vertical grinder topulverize the raw materials, and it recycles the waste gas generatedby the pre-heaters to dry the powdered materials. After classified bythe fine powder classifier, the pulverized materials are mixed withthe dust collected by the humidifying tower and the electric dustcollector, and then delivered by the chute and bucket elevator to theraw material homogenization silo. The waste gas generated during theprevious steps is treated by an electric dust collector before it isdischarged into the air.

3. Raw material homogenization

The pulverized raw materials firstly enter into thehomogenization silo in a multipoint way with the help of a rawmaterial distributor, and then are unloaded into a temporary storagesystem with weight and flow measuring devices. Finally, they are fedinto the pre-heating system at the kiln end by the bucket elevatorafter measuring.

4. Cement clinker sintering and storage

Thesintering furnace is mainly composed of a five-stage preheater withlow pressure loss, a decomposing furnace, and a new-type flow-controlcooler unit which are all designed based on NCDRI technology.

(1)The sintered clinker is firstly cooled by the cooler unit, and can besent to storage by the bucket chain conveyor and pan conveyor.Finally, the material will be transferred to the cement batchingstation.

(2) The heat gas at the high temperature end of thecooler unit is partly utilized as the burning gas of the decomposingfurnace, and the gas at the medium-temperature section is utilized todry the raw coal in the coal mill. The waste gas after treated by theelectric dust collector is finally discharged into the air. Ourcement production line can make sure the dust content in thedischarged waste gas is less than 100mg/m3.

5. Raw coalstorage and conveying, as well as coal powder preparation anddelivering

The incoming raw coal is stored in a warehouse forstorage and pre-homogenization. The raw coal warehouse is designedwith two silos, which reduces the travel distance of the cranes andsupports storage of coal materials of different types. Weigh feedersare available at the bottom of the two silos. Thus, the raw coalmaterials can be accurately weighed before they are sent to the coalmill for pulverizing. The coal powder materials are firstly processedby the classifier, and then collected by the pulse bag dustcollector. Finally, they are delivered to two powder coal storagesilos, and the waste gas is treated before discharged. The powdercoal storage silo is also equipped with measuring device, and themeasured materials are transferred to the kiln head and decomposingfurnace.

6. Slag drying and conveying, as well asgypsum crushing and delivering

The incoming slag and gypsum canbe stored in outdoor storage yards. During the material preparationprocess, forklift trucks can be utilized to transfer the slag intothe bucket elevator which will deliver the slag material into thedryer for drying. The gypsum will be fed into the hammer crusher bythe heavy duty plate feeder for crushing. The crushed gypsum isfinally delivered into the gypsum storage silo by the bucket elevatorthe rubber belt conveyor.

7. Cement grinding, conveying, andstorage

The cement batching station includes four storage silosfor the clinker, gypsum, limestone, and slag respectively. Eachsilo’s bottom is designed with a weigh feeder which ensuresmaterial discharging in accordance with preset proportion. Theclinker storage silo is designed with an additionally device tofacilitating outgoing-transportation of the cement clinker. The fourkinds of materials, after discharged from the silos in proportion,will be conveyed by the rubber belt conveyor to two cement grindingsystems which are made of a ball mill and highly efficient powderclassifiers. The pulverized materials are treated by the powderclassifier, and the coarse materials are sent back for pulverizationagain. The finished cement is firstly collected by the pulse bag dustcollector, and then delivered to the cement warehouse by the chuteand bucket elevator.

For the purpose of environmental protection,the cement production line adopts the pulse bag dust collector totreat the waste gas generated during cement grinding process.

Thecement warehouse should be equipped with a material dischargingsystem at the bottom part. After material discharging, the materialis conveyed by the rubber belt conveyor, bucket elevator, and chuteto the cement packaging workshop and bulk cement warehouse.

Ourcement manufacturingplantincludes two rotary packagingmachines for cement packaging. The packaged cement is finallytransferred to the end product warehouse for storage, and can also beloaded onto trucks for transportation directly.

The bulk cementwarehouse is designed with facilities to allow truck transportationof the bulk cement directly.

Links:https://globefindpro.com/products/38506.html

-

3-300Kt/a SSP/GSSP Fertilizer Plant

3-300Kt/a SSP/GSSP Fertilizer Plant

-

Special Inkjet Media Products

Special Inkjet Media Products

-

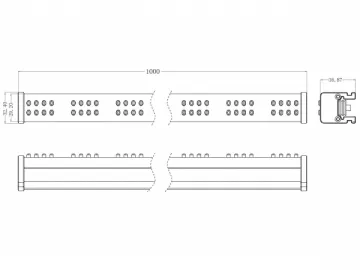

Aluminum Sheet Water Jet Cutting Machine

Aluminum Sheet Water Jet Cutting Machine

-

Waterproof LED Strip Light

Waterproof LED Strip Light

-

Matte Coated Inkjet Paper

Matte Coated Inkjet Paper

-

40mm LED Point Source Light

40mm LED Point Source Light

-

Color Laser Paper

Color Laser Paper

-

Granite Water Jet Cutting Machine

Granite Water Jet Cutting Machine

-

Titanium Water Jet Cutting Machine

Titanium Water Jet Cutting Machine

-

CNC Waterjet Cutting Machine

CNC Waterjet Cutting Machine

-

Format Roll Size Inkjet Photo Paper (Plotter)

Format Roll Size Inkjet Photo Paper (Plotter)

-

Copper Water Jet Cutting Machine

Copper Water Jet Cutting Machine