150W/180W Laser Tube for Laser Machine

Models of 150W Laser Tube

Model of 180W Laser Tube

Product Merits

CO2 laser tubes with an output power of either 150W or 180-W are characterized by strong energy levels, excellent beam modes, sufficient laser power, a long service life, and reliable stability. These sealed CO2 laser devices can be used for laser cutting on acrylic, textiles, leather products, wood, sheet metal and more.

These reliable, stable, high powered and high speed spare parts for laser cutting machine, including the F8, ZN1850 and ZX1850 CO2 laser tubes, play a vital role, in laser cutting for different materials, and are a top choice among laser cutting machine manufacturers. They are applicable to a majority of laser cutting machines and are used to cut sheet metal, die cutting boards, thick organic glass and more.

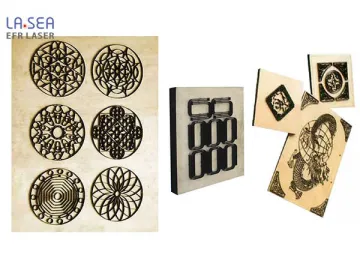

Application Examples

Laser cutting is essential in the processing of stainless steel, carbon steel, metal plates and other metal materials. Laser cutting machines are widely used in machinery manufacturing and processing in a number of industries, including construction, petroleum, food processing, household appliances, special vehicles, agriculture, forestry, environmental protection, aerospace engineering and more. Laser cutting tools equipped with high quality laser cutting machine accessories, like EFR's CO2 laser tubes, can allow the finished products to have a higher quality and additional value.

Finished Product Display

Advantages

1. A high precision, fast speed and narrow kerf width of 0.1mm - 0.2mm.

2. A smooth and burr free cutting surface, with a surface roughness of ≤Ra12.5

3. Non-contact laser cutting, and one-time high quality cutting ensure the work piece is not damaged or deformed.

4. Materials with different hardness levels and shapes are applicable.

5. Non-metallic materials, including plastic, wood, PVC, leather, textile, organic glass and more are applicable

6. Computer programming and a short production cycle that requires no molds saves time, cost and materials.

Links:https://globefindpro.com/products/38760.html

-

130W Laser Tube for Laser Machine

130W Laser Tube for Laser Machine

-

Tempering Furnace

Tempering Furnace

-

Structural Steel Testing Equipment

Structural Steel Testing Equipment

-

Transport Industry

Transport Industry

-

Plant Facts

Plant Facts

-

Pharmaceutical Industry

Pharmaceutical Industry

-

Machinery and Equipment

Machinery and Equipment

-

Inner Package Option

Inner Package Option

-

Solutions to Refrigerated Display Cabinet

Solutions to Refrigerated Display Cabinet

-

BDS Core Value

BDS Core Value

-

Line Reactor (for Washing Machine)

Line Reactor (for Washing Machine)

-

Solutions to Laundry Equipment

Solutions to Laundry Equipment