Wastewater in Textile Dyeing Industry

1. Textile dyeing industry is the main source of discharging the industrial wastewater. Dyeing wastewater is referred to a mixture discharged from all procedures of the printing and dyeing process. Its characteristics include high concentration of organics, high-degree and varied color, great pH variation, as well as enormous change of both flow and water quality. Hence, this kind of industrial wastewater is hard to be handled. It gradually threatens and damages the environment, especially the water environment.

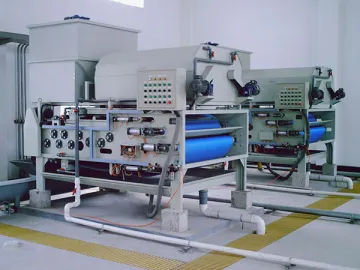

2. A notable textile mill in Guangzhou can offer the sewage processing capacity of up to 35,000m3 daily. By adoption of the contact oxidation method, it can provide high sludge output but low solid content. Thus, pre-concentration is needed prior to the dewatering process. This company bought three HTB-2500 series rotary drum thickening-dewatering belt filter presses from our company in April, 2010. Our equipment has so far operated smoothly, thereby receiving a high reputation from our customers. Additionally, it is highly recommended by our clients within the same industry.

3. A customer from Mauritius immediately purchased a HTB3-1250 series belt filter press from our company, after visiting the site in 2011. This machine has been successfully installed and commissioned in December, 2011. Up to now, no failure has occurred during operation.

Treatment Effect Drawing

in Shaoxing Textile Factory

Treatment Effect Drawing

in Shaoxing Textile Factory

Site in Mauritius

Site in Mauritius

4. The rotary drum thickening-dewatering belt filter press of HaiBar is well received by an increasing number of dyeing and printing enterprises, because it gives great processing capacity, continuous operation, low operating cost, low water content, convenient maintenance, and other advantages. After investigating our filter-press operation site, many manufacturers have already purchased our products instead of the original chamber filter press or plate-and-frame filter press.

Links:https://globefindpro.com/products/39157.html

-

198A Non Sparking Long Handle Square Shovel

198A Non Sparking Long Handle Square Shovel

-

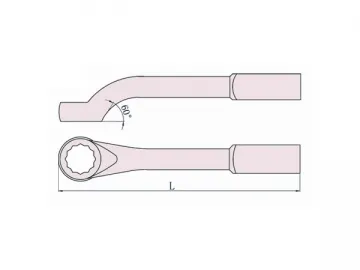

180 Non Sparking Ratcheting Box Wrench

180 Non Sparking Ratcheting Box Wrench

-

Industrial Building

Industrial Building

-

192B German Type Non Sparking Sledge Hammer

192B German Type Non Sparking Sledge Hammer

-

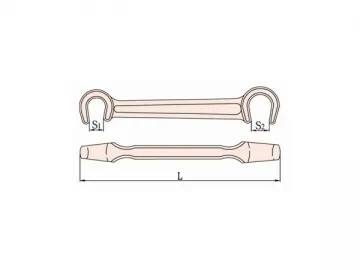

169 Non Sparking Double C Spanner

169 Non Sparking Double C Spanner

-

Slaughterhouse Wastewater

Slaughterhouse Wastewater

-

Ferrous Metallurgy Wastewater

Ferrous Metallurgy Wastewater

-

192A Non Sparking Sledge Hammer

192A Non Sparking Sledge Hammer

-

163A American Type Non Sparking Offset Box End Slogging Wrench

163A American Type Non Sparking Offset Box End Slogging Wrench

-

Belt Filter Press Systems for Sludge Dewatering, Sludge Dewaterer

Belt Filter Press Systems for Sludge Dewatering, Sludge Dewaterer

-

191C German Type Non Sparking Sledge Hammer

191C German Type Non Sparking Sledge Hammer

-

179A Non Sparking Single End Drum Wrench

179A Non Sparking Single End Drum Wrench