Top Hammer Drill Rods

Top hammer drill rod performs power transmission works in the drilling process, via which power from rock drill piston is transmitted to drill bits, and finally delivered into rocks. One side of the drill rod is connected to coupling or directly to the shank adapter, while the other side is connected with drill bit. Top hammer drill rods are suitable for drilling works for blasting duties in tunneling, construction, mining, quarrying, etc.

Drilling duties in tunneling, construction, mining, quarrying, etc.

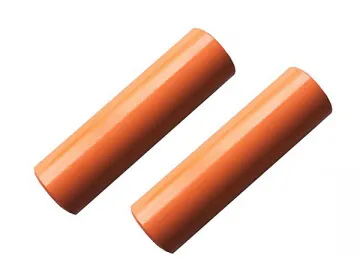

Integral Drill RodConnected to rock drill, the integral drill rod can be directly deployed for drilling.

Parameters Rock drill connection: H22*108mm Diameter: 26mm-41mm Length: 800mm-8000mm Taper Drill RodWith one side connected to rock drill and the other side connected with taper drill bit, the taper drill rod transmits power from rock drill to bit, drilling work is thus performed.

Parameters Rock drill connection: H22*108mm Conical degree: 4°46’ , 6°, 7°, 11°, 12° Length: 400mm-8000mmMF Drill Rod

Extension Drill Rod

Extension drill rod transmits power from rock drill piston to rock, one side of the rod is connected to coupling or shank adapter, while the other side is connected with threaded drill rod.

Parameters Thread type: R25, R28, R32, R38, T38, T45, T51 Diameter: Hex.22, Hex.25, Hex.28, Hex.32, Hex.35.Round 32, Round 39, Round 46, Round 52. Length: 600mm-6095mm Slot for wrench: with or without Industries We Serve

Our rock drilling equipment can be applied in various industries, doing rock drilling and crushing duties for digging, blasting, etc.

We mainly offer 4 series of rock drilling tools: top hammer drilling tools, down-the-hole (DTH) drilling tools, self-drilling anchor system and drag bits.

Links:https://globefindpro.com/products/3997.html