HQR 400D Rotary Drilling Rig

Features

1. The main winch is located at the bottom of the drilling mast to offer an excellent angle for checking line work. The unique design in the roll prolongs the service life of the steel line and enhances the construction safety. The excellent pulley design adjusts the steel line to the best position, and enhances the reliability of the overall rotary drilling rig.

2. A supercharging technique allows the crowd pull force to reach 44T and the crowd stroke to reach 14m. This design meets a variety of construction methods.

3. The rotary drilling rig features an original CAT374D engine and up structure. The crawler can adjust between 2900 and 4500mm. Customers can choose the counterweight, and increase the weight to improve stability and reliability.

4. Key parts in the hydraulic system are similar to those in the CAT hydraulic loop. Advanced main and auxiliary hydraulic systems achieve the flow allocation and sensitivity loading according to operation demands and drive functions. These features offer a more reliable performance throughout the construction process.

Parameter:

| Model | HQR400D Rotary Drill Rig |

| Maximum output torque(KN.m) | 400 |

| Maximum drilling depth(m) | 106 |

| Maximum drilling diameter(mm) | 3000 |

| Engine brand | CAT |

| Engine model | C-15 C-15ETF |

| Engine power(KW) | 350 |

| Undercarriage model | CAT374D |

| Traction force(KN) | 896 |

| Drilling speed(rpm) | 6/22 |

| Maximum crowd push force(KN) | 440 |

| Stroke of sledge(mm) | 14000 |

| Main winch pull(1st layer) | 350 |

| Main winch wire rope diameter (mm) | Φ40 |

| Maximum main winch line speed(m/min) | 66 |

| Auxiliary winch line pull(1st layer)(KN) | 120 |

| Auxiliary winch wire rope dia.(mm) | Φ20 |

| Auxiliary winch line speed(m/min) | 75 |

| Overall width in drilling position(mm) | 5500/27638 |

| Overall L/H/W transport position(mm) | 19500/3900/4100 |

| Total weight (t) | 132 |

Links:https://globefindpro.com/products/41235.html

-

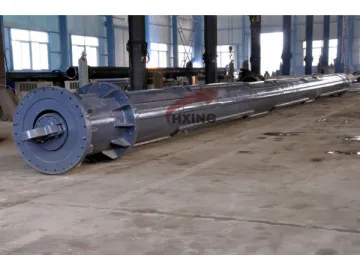

Kelly Bar for BAUER Drilling Rig

Kelly Bar for BAUER Drilling Rig

-

Intelligent Ozone Generator

Intelligent Ozone Generator

-

Venturi Injector and Mixing Pump

Venturi Injector and Mixing Pump

-

Details Show

Details Show

-

Kelly Bar for Chinese Brand Drilling Rig

Kelly Bar for Chinese Brand Drilling Rig

-

Pressurizing Block

Pressurizing Block

-

HQR 280D Rotary Driling Rig

HQR 280D Rotary Driling Rig

-

SANY Rotary Drilling Rig Kelly Bar

SANY Rotary Drilling Rig Kelly Bar

-

HQR 160Z Rotary Driling Rig

HQR 160Z Rotary Driling Rig

-

HQR 360Z Rotary Driling Rig

HQR 360Z Rotary Driling Rig

-

Ozone Monitor

Ozone Monitor

-

Kelly Bar Square Adapter

Kelly Bar Square Adapter