Two Color TPE Shoe Cover Injection Molding Machine

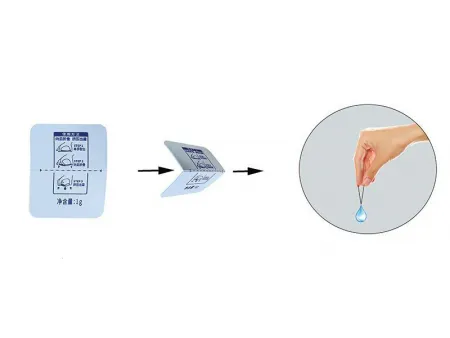

Rotary injection molding machine for producing shoe covers and galoshes The TPE injection molding machine is used to produce rain boots and shoe covers in one color and two colors; The mold closing process is stable and reliable, and the clamping force is balanced to ensure high product quality; The structure of molds is simple for easy replacement and maintenance.  Technical Specifications

Technical Specifications

Features The injection molding machine is widely used to make TPE shoe cover in one color and two colors; The TPE injection machine is equipped with an industrial interface, a PLC and a touchscreen; The dual-ratio hydraulic control valve precisely controls the injection pressure and the rate of flow to produce high-quality shoe covers; The digital measurement system ensures stable production performance; The touch panel is designed to be simple and easy to operate; Our fabulous injection machine is equipped with a robotic arm to realize fully automatic production; The servomotor system reaches the same performance with less energy consumption compared to traditional motors.

Raw material: TPE

Applications:

one-color and two-color shoe covers

| Item | Unit | Specifications | |

| Model | 612AC (adult) | 612BA (kids) | |

| Raw material | TPE | TPE | |

| Number of stations | 12 (14 or 16) | 12 (14 or 16) | |

| Max. injection volume | cm³/cc | 770, 1270 | 500, 770 |

| Rated injection pressure | kg/cm² | 0-120 | 0-120 |

| Power of electric heating | kW | 13 15 | 9 13 |

| Temperature setting | stage | 5 | 5 |

| Screw rotational speed | RPM | 0-150 | 0-150 |

| Screw diameter | mm | Ø70,Ø90 | Ø55,Ø70 |

| Motor power | kW | 15,22 | 15,18.5 |

| Clamping force | T | 250 | 250 |

| Max. mold size | mm | 680*360*200 | 520*360*200 |

| Machine dimensions | mm | 5500*5050*2450 | 5710*4720*2170 |

| Gross weight | kg | 18500 | 16800 |

Scan QR to Read

Links:https://globefindpro.com/products/413.html

Links:https://globefindpro.com/products/413.html

Recommended Products

Hot Products