Semi-Automatic Rotary Varnishing Machine, SRF-330

SRF-330

Technical parameters

Standard configuration

Detail Configuration

Samples

The SRF-330 semi-automatic rotary varnishing machine is the best solution for digital converting processes such as flexographic coating and finishing. Driven by a servo-motor system, the rotary flexographic coating machine works in both rotary and semi-rotary modes with register, spot varnishing and flood coating. Optional IR dryer and UV curing system.

Technical parameters

| Max Coating Speed | 300Cycles/Min |

| Accuracy of Print | ± 0.15 mm |

| Max Print Area | 320mmX 450mm (W*L) |

| Paper Width | 330mm |

| Max Unwinding Dia . | 700mm |

| Max Rewinding Dia . | 700mm |

| Standard Print Cylinder | 160Teeth 1/ 8" CP(Standard) |

| UV Power | 7.5kW |

| IR Power | 12KW |

| MOTOR Power | 8KW |

| Overall Diameter ( L×W×H ) | 2500*1600*1600 |

| Weight | 1700KGS |

Standard configuration

A: Unwinding

B: Web Guider

C: 160 teeth printing cylinder (unchangeable)

D: Servo motors (Panasonic imported from Japan)

E: HMI touch screen operating system (Schneider PLC)

F: Slitter

G: Rewinder and waste matrix mandrels

Detail Configuration

| Part | SRF-330 |

| Main Control System | TRIO system (UK) |

| Tension | P F/ultrasonic system (German) |

| Powder Clutch | Leesun (Taiwan) |

| Web Guiding | BST (German) |

| Servo Motors | Panasonic (Japan) |

| Sensors | Leuze (German) |

| Touch Screen | Schneider |

| Reducer | Apex (Taiwan)*4/or Shimpo(Japan) |

| Electric Components | Schneider |

| Gears and Bearings | NSK (Japan) |

| Screws | 12.9 Levels |

| Magnetic Cylinder | Rotary (CN) |

| Power Switch | Schneider |

| Pneumatic Switch | Schneider |

| Switch | Meanwell (Taiwan) |

Note: The listed parts may change.

Samples

Scan QR to Read

Links:https://globefindpro.com/products/41739.html

Links:https://globefindpro.com/products/41739.html

Recommended Products

-

TOP-330HT Intermittent/Full Rotary Cutting Machine

TOP-330HT Intermittent/Full Rotary Cutting Machine

-

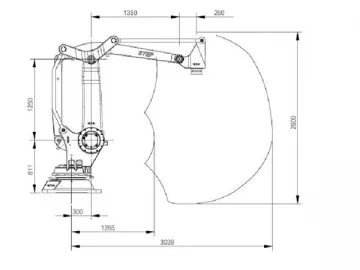

Industrial Robot, SP275

Industrial Robot, SP275

-

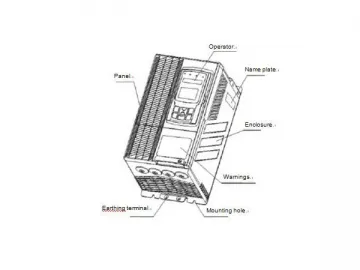

Medium Voltage Drive, AS800 Series

Medium Voltage Drive, AS800 Series

-

Rotary Die Cutting Machine , IML-520 IML

Rotary Die Cutting Machine , IML-520 IML

-

Frequency Inverter (for Construction Hoists), AS620 Series

Frequency Inverter (for Construction Hoists), AS620 Series

-

TOP-330-2 Multi-Functional Label Die Cutting Machine

TOP-330-2 Multi-Functional Label Die Cutting Machine

-

Label Inspection Machine

Label Inspection Machine

-

Vector Inverter (General Purpose), ES450 Series

Vector Inverter (General Purpose), ES450 Series

-

TOP-520 Intermittent / Full Rotary Cutting Machine

TOP-520 Intermittent / Full Rotary Cutting Machine

-

Rotary Die Cutting and Finishing Machine, TOP-330 Ultra Flexo

Rotary Die Cutting and Finishing Machine, TOP-330 Ultra Flexo

-

IML-330 Full Rotary Die cutting Machine

IML-330 Full Rotary Die cutting Machine

-

TOP-330 Intermittent/Rotary Cutting Machine

TOP-330 Intermittent/Rotary Cutting Machine

Hot Products