Laser Cutting Machine

This powerful laser cutting machine designed by ACCURL is equipped with a YAG lamp pump laser generator. The CNC laser cutter is suitable for high speed, large scale sheet metal cutting operations.

A remote controlling device allows multiple laser systems to be operated at once without having to physically interact with each device, greatly saving time and increasing efficiency.

The laser cutting machine can be fitted with a rotary device to perform position punching and cutting of metal sheet.

Additional Features of the Laser Cutting Machine

1. The sheet metal cutting machine is equipped with a 650 or 800watt laser generator that has a versatile cutting area of 1500mmx3000mm (or 1300x2500mm, 1300x900mm).

2. Stable and deformation resistant. Aging process technology ensures durable use and accuracy of the machine.

3. Automatic focus device realizes dynamic focusing for continuous cutting on materials with varying thicknesses.

4. The working table is equipped with a universal wheel and an optional pneumatic loading device, saving labor and avoiding metal sheet damage.

5. Automatic nesting software and optional collocation auto-recognition cutting saves materials and improves working efficiency.

YAG Laser Cutting Machine Technical Parameters

| Laser Type | YAG lamp pump solid state laser generator |

| Laser Wavelength | 1064nm |

| Laser Power | 800W, 650W,500W |

| Cutting Area | 1500mm x 3000mm, 1300mm x 2500mm, 1300X900mm |

| Working Table | Saw tooth working table |

| Motion System | Digital offline control system; YASKAWA servo motor; ABBA high precision ball screw; REXROTH linear guide transmitting system |

| Min. Kerf | 0.15mm (1mm thickness) |

| Min. Bore Diameter | 0.2mm to 0.5mm |

| Repeat Position Accuracy | ± 0.05mm |

| Max. Cutting Thickness | Ferrous metal: 10mm carbon steel, 8mm stainless steel (blow dry filtered compressed air) |

| Cooling System | External constant-temperature water chiller system |

| Software | Golden Laser Auto Nesting Laser Cutting Software |

| Format Supported | PLT, DXF, AI, DST, etc |

| Other Standard Collocation | Remote controller, drawer rewind device |

| Optional Collocation | Integrated rotary device (X axis); detached rotary device (Y axis); pneumatic loading device |

| Auxiliary Gas | Dry filter compressed air : carbon steel, stainless steel, aluminum, brass and copper |

| Suggested auxiliary gas | Dry filter compressed air |

| Main power | 22KW, 18KW |

| Power supply requirement | 380V± 5% 50/60HZ 100A (3 phase 5 wire) |

| Floor space requirement | 4500mm x 4500mm |

| Workshop environment | Temperature 0-40 Centigrade, Humidity 45-85%, good ventilation, no corrosive gas, etc |

| Shipping container | 20GP FCL |

Links:https://globefindpro.com/products/41974.html

-

Constant Tension Clamp

Constant Tension Clamp

-

Double Wire Hose Clamp

Double Wire Hose Clamp

-

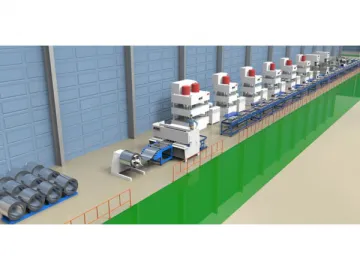

Automatic Production Line (Metal Forming)

Automatic Production Line (Metal Forming)

-

Make A Clamp Kit (with Perforated Band)

Make A Clamp Kit (with Perforated Band)

-

Heavy Duty Bolt Clamp (with Double Band)

Heavy Duty Bolt Clamp (with Double Band)

-

H-frame Hydraulic Press(Deep Drawing)

H-frame Hydraulic Press(Deep Drawing)

-

No-Hub Coupling, Type E

No-Hub Coupling, Type E

-

Double Ear Clamp

Double Ear Clamp

-

No-Hub Coupling (EN877 Standard), Type B

No-Hub Coupling (EN877 Standard), Type B

-

Four-Column Hydraulic Press (for SMC Molding)

Four-Column Hydraulic Press (for SMC Molding)

-

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

-

Four Column Deep Drawing Press HBP-40T~1600T

Four Column Deep Drawing Press HBP-40T~1600T