Rotary Screw Air Compressor (Integrated with a Freeze Dryer and Filter)

When compressed air quality matters, consumers need a high performance rotary screw air compressor that is reliable and efficient. The GD series screw air compressor is manufactured with a freeze dryer and filter, providing a consistent air quality that is oil, water and dust free.

Diverse industries including electronics, pharmaceutical and textiles require the use of quality air compressor equipment and compressed air solutions.

As our general purpose air compressors are reliable, compact and quiet, they have become a popular choice for supplying clean air to various industrial factories in residential areas.

When running at 22kw, the general purpose air compressor creates a noise level as low as 66dB without causing any vibrations. The one-piece compressor design allows for an easy installation, use and maintenance.

Technical Specifications

| Model Code. | Operating Pressure (bar) | Volumetric Flow Rate (m3/min) | Motor Power(kw/Hp) | Noise LeveldB(A) | Dimensions (mm) | Weight (kg) | Outlet Pipe Diameter G |

| GD11 | 7/8/10 | 1.6/1.5/1.4 | 11/15 | 62 | 110×700×1250 | 440 | G3/4 |

| GD15 | 7/8/10 | 2.5/2.3/2 | 15/20 | 64 | 1150×830×1450 | 625 | G3/4 |

| GD18 | 7/8/10 | 3/2.9/2.7 | 18.5/25 | 66 | 1150×830×1450 | 658 | G1 |

| GD22 | 7/8/10 | 3.6/3.5/3.2 | 22/30 | 66 | 1150×830×1450 | 680 | G1 |

| GD30 | 7/8/10 | 5.2/5.0/4.5 | 30/40 | 66 | 2040×970×1800 | 1100 | G1-1/4 |

| GD37 | 7/8/10 | 6.7/6.3/6 | 37/50 | 67 | 2040×970×1800 | 1150 | G1-1/2 |

| GD45 | 7/8/10 | 8/7.5/6.9 | 45/60 | 67 | 2040×970×1800 | 1200 | G1-1/2 |

**Note: The above models are for reference only. We can provide a range ofcustomized screw compressor products for our customers.

Functions/Protections

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | √ |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

VI. Display, Alarm, Interlock (power failure protection)

| Items | Display | Alarm | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |

Links:https://globefindpro.com/products/43035.html

-

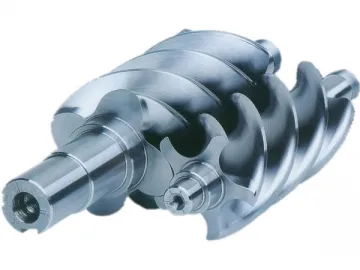

Screw Air End

Screw Air End

-

Tungsten Carbide Machine Knives ( Circular Knives for Cutting Lithium Battery Materials)

Tungsten Carbide Machine Knives ( Circular Knives for Cutting Lithium Battery Materials)

-

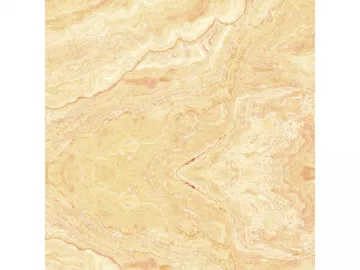

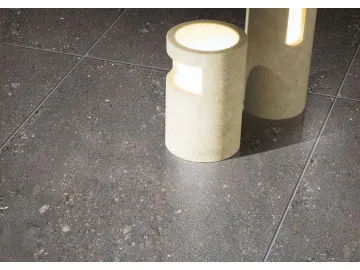

SHINING TEMPTATION Series Glazed Porcelain Tile

SHINING TEMPTATION Series Glazed Porcelain Tile

-

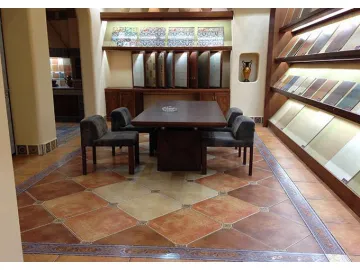

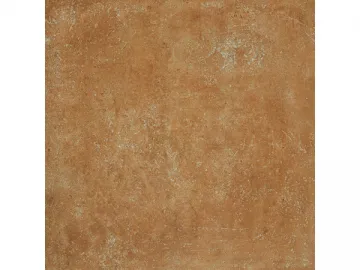

POLIS Series Rustic Tile

POLIS Series Rustic Tile

-

Rotary Screw Air Compressor (Economical Type)

Rotary Screw Air Compressor (Economical Type)

-

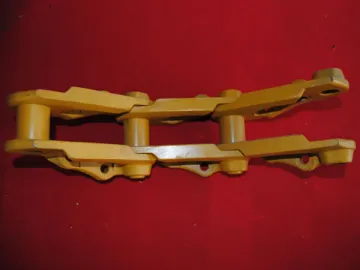

Track Chain

Track Chain

-

Rotary Screw Air Compressor (Compact Screw Compressor)

Rotary Screw Air Compressor (Compact Screw Compressor)

-

Rotary Screw

Rotary Screw

-

Rotary Screw Air Compressor (Fixed Speed)

Rotary Screw Air Compressor (Fixed Speed)

-

GUANYIN WALL Series Polished Porcelain Tile

GUANYIN WALL Series Polished Porcelain Tile

-

METAMORPHOSIS Series Glazed Porcelain Tile

METAMORPHOSIS Series Glazed Porcelain Tile

-

CITY Series Glazed Porcelain Tile

CITY Series Glazed Porcelain Tile