HY-QM Series Automatic Rotary Die Cutter

Main Features of HY-QM Series Automatic Rotary Die Cutter

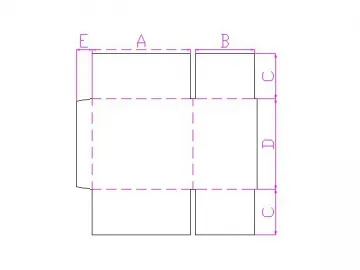

1. The HY-QM series automatic rotary die cutter is used for making special cartons. This rotary die cutting machine employs advanced lead edge feeder with suction hold-down device. This feeding method boasts faster speed, high accuracy and lower failure rate as compared with back kicking feeding way.

2. Thanks to this best-in-class feeder, both continuous and skip feeding can be achieved.

3. The carton making machine is equipped with IR number counter that allows you to know production quantity clearly. Alarm bell make operation safer.

4. The die cut roller of this automatic rotary die cutter is made of superb quality steel. It has been processed by balance alignment and hard chrome plating treatment.

5. When feeding starts, the die cut roller will rise pneumatically and touch the cushion roller; when feeding stops, it will automatically down.

6. The rubber cushion is extremely endurable and easy to install and disassemble.

7. The cushion roller comes with automatic linear speed compensation mechanism which enables the rubber cushion to be worn uniformly. Equipped with repair system, the rubber cushion can serve for a long time and make die cutting beautiful.

8. The automatic rotary die cutter is provided with a cam-type mechanical device that allows the cushion roller to move left and right about 40mm and thereby increase its service life.

8. The die cutting knife phase adjustment is controlled by computer or motor.

9. Lateral movement of the die cutting knives can also be adjusted by computer or motor. The adjustment range is ±5mm.

10. This series automatic rotary die cutter boasts speed compensation device which makes sure that all boxes enjoy the uniform size.

11. Spray lubrication system can prolong the service life of gears.

12. Control system is imported from world famous manufacturer. For example, the low voltage electric appliance is introduced from Simens. Main motor adopts frequency converting control, thus saving 30% power.

Technical Parameters HY-QM Series Automatic Rotary Die Cutter

| Name of Parameter | Unit | Specification | |||

| QM-410-1600 | QM -410-2400 | QM -530-2400 | QM -530-3000 | ||

| Max. Machine Speed | sheet/min | 120 | 120 | 120 | 120 |

| Max. Sheet Size | mm | 1400×1600 | 1400×2400 | 1650×2400 | 1650×2900 |

| Max. Die Cutting Size | mm | 1400×1350 | 1350×2200 | 1600×2200 | 1600×2700 |

| Paperboard Thickness | mm | 1.5-11 | 1.5-11 | 1.5-11 | 1.5-11 |

Note:

Machine size can be designed according to your demands.

Links:https://globefindpro.com/products/43481.html

-

Corrugated Cardboard Stacker

Corrugated Cardboard Stacker

-

HY-GM Series Semi-Auto Rotary Die Cutter

HY-GM Series Semi-Auto Rotary Die Cutter

-

Twin Head Semi-Auto Stitcher

Twin Head Semi-Auto Stitcher

-

SMQ500D Telescopic Crawler Crane

SMQ500D Telescopic Crawler Crane

-

Hydraulic Shaftless Mill Roll Stand

Hydraulic Shaftless Mill Roll Stand

-

NC Slitter Scorer

NC Slitter Scorer

-

Electric Shaftless Mill Roll Stand

Electric Shaftless Mill Roll Stand

-

Corrugated Cardboard Preheater

Corrugated Cardboard Preheater

-

BFY Series Slitter Scorer

BFY Series Slitter Scorer

-

ML Series Die Cutting and Creasing Machine

ML Series Die Cutting and Creasing Machine

-

SMQ500A Telescopic Crawler Crane

SMQ500A Telescopic Crawler Crane

-

HY-B Series Semi-Auto Rotary Slotter

HY-B Series Semi-Auto Rotary Slotter