HT2512UV FG12 UV Flatbed Printer

Designed with high reliability and performance, the FG12 UV flatbed printer helps you to save a big sum of printing costs. It is a versatile device capable of printing, bringing you high returns and low investment risk. Optionally matched with production line print mode, it fits for industrial online production.

Overall Descriptions

This UV printer is outfitted with 4-12 Ricoh grayscale piezoelectric print heads, able to print in 6 colors and with high precision of 720×1200 dpi. By virtue of high production speed of 36m2/h (4 pass), it is well suited to mass production. Meanwhile, optional template printing system decreases splicing error down to below 0.5mm.

The working platform of our UV flatbed printer is designed with precision screw (dual grinding) motion control system to ensure perfect positioning of rigid and flexible materials. Repeat positioning precision reaches up to 0.02mm×0.02mm. Besides, this flatbed printing machine can be optionally configured with white ink and gloss paint printing systems to meet different usage requirements.

Features

1. High Precision

a. Drop-on-demand printing is available, and ink drop ranges from 7pl to 21pl. What’s more, this print mode can achieve photo-grade precision, and printing in 2pt font is available.

b. Max. resolution ratio: 1200×800 dpi

c. Our UV flatbed printer comes with screw (dual grinding) motion control system to guarantee stable and accurate guide rail movement.

d. Fixed linear raster is utilized, making for high-precision positioning of print head trolley.

e. Thanks to special-purpose stop lever, material loading is more convenient and precise. Additionally, deviation won’t occur during repeat print.

2. High Speed

a. 4-pass bi-direction printing: 36m2/h

b. 6-pass bi-direction printing: 27m2/h

c. 8-pass bi-direction printing: 20m2/h

3. Multiple Functions

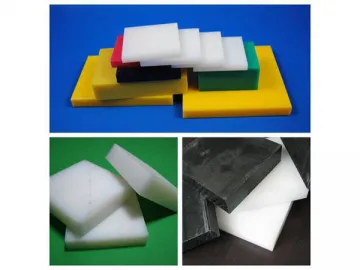

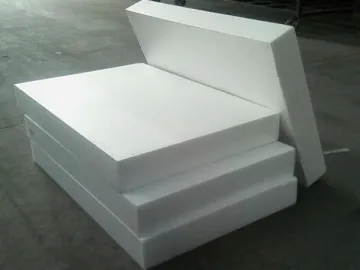

a. Max. applicable material thickness: 100mm

b. Loading platform size: 2.5m (width) × 1.22m (depth)

c. This print press is suitable for materials like glass, acrylic, wood board, ceramic, metal plate, PVC board, corrugated board, plastic, etc.

d. Color modes:

CMYK × 2

CMYKWV × 2

CMYKLcLm × 2

e. Our UV flatbed printer enables 16 white-ink printing modes including automatic white ink over and under-printing, white substrate printing and pantone printing. Besides, 3 types of gloss paint is available for flatbed printing.

f. Max. load bearing capacity of printing platform: 50kg/m2 (in flat arrangement)

g. Our UV flatbed printer is especially suited for materials susceptible to thermal deformation, for its ultra strong vacuum absorption system can make materials firmly attached to working platform.

6. Ink Saving

Our UV flatbed printer saves ink by 30%-50%.

7. Eco-friendly

This flatbed printer adopts environment friendly UV-curable ink without VOC (volatile organic compound).

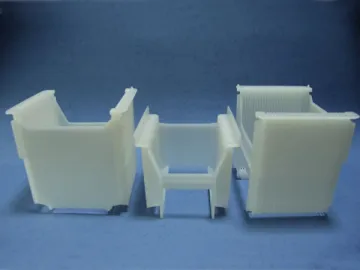

8. Wide Application Range

In virtue of rich colors and high efficiency, the UV flatbed printer has gradually replaced traditional screen printer in partial application fields, and the UV-curable ink it adopts is suitable for direct printing. Till now, this machine has been extensively applied in panel, furniture board, suspended ceiling, wood floor, ceramic, and other industries.

Technical Parameters

| Model | HT2512UV FG12 | ||

| Nozzle | Ricoh grayscale piezoelectric print head | ||

| Nozzle quantity | 4-12 | ||

| DPI | 1440×1200 dpi | ||

| Print mode | Uni-directional and bi-directional | ||

| Print speed | 4 Pass | 6 Pass | 8 Pass |

| 36m2/h | 27m2/h | 20m2/h | |

| Platform size | 2.5m×1.22m | ||

| Medium | Rigid and flexible board materials | ||

| Medium thickness | Max. 100mm | ||

| Applicable medium | Glass, acrylic, wood board, ceramic, metal plate, PVC board, corrugated board, plastic, etc. | ||

| Ink | Environment friendly UV-curable ink free from VOC, 3L/barrel | ||

| Ink color | CMYKLcLm, free combination | ||

| Special ink | UV white ink or UV transparent gloss paint (Optional when LcLm is unavailable) | ||

| Input format | Adobe Postscript Level 3, PDF, JPEG, TIFF, EPS, AI | ||

| Software interface | Seeget, Onyx, Caldera | ||

| Net weight | 1200kg | ||

| Overall dimension | 130cm (height)×190cm (width)×480cm (length) | ||

| Power | 6.5KW (32A) | ||

| Electrical requirement | 220VAC (±10%) single phase, 50/60Hz | ||

| Environmental requirement | a. Independent, clean, less-dust, less-light, well-ventilated workshopb. Ambient temperature: 18ºC-30ºC (64ºF-86ºF) c. Relative humidity: 30%-70% (non-condensing)d. Ventilating device: Overhead exhaust fan is recommended with 600cfm exhaust volume. | ||

| Certification | CE, FCC | ||

| Note: The above parameters are subject to actual equipment and change without prior notice. | |||

Links:https://globefindpro.com/products/44366.html