SBH290W Automatic Block Bottom Paper Bag Machine

SBH290W

Optional equipment

Servo window die cutter unit

Servo film patching unit

Servo two layer unit

Carrier bag with

a cord handle

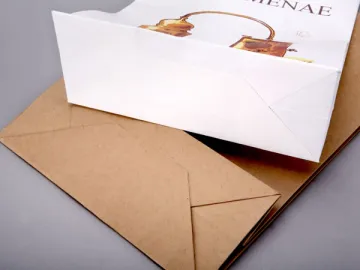

Two-layer block

bottom bag

Block bottom bag

with see-through

window

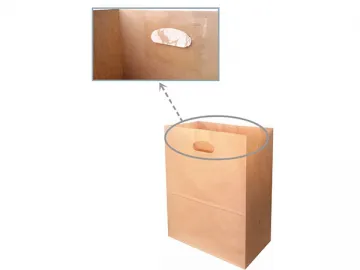

Block bottom bag

Cut-off handle

block bottom bag

Specification

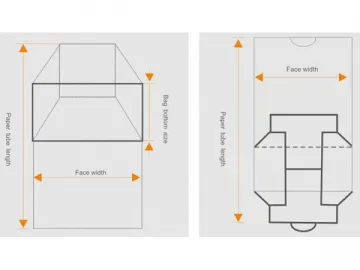

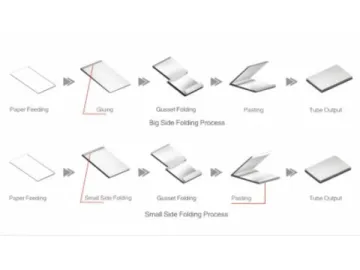

Based on SBH290 range of paper bag making machine, SBH290W automatic block bottom paper bag machine features window die cutter device for double layers. Thus, SBH290W is capable of producing both cut-out handle SOS paper bag and all paper bags of SBH290 model.

Standard features of the block bottom paper bag machine include servo technology and these machines are ready for additional units in terms of electrical control. Servo film patching unit, servo window die cutting unit, and servo two layer unit can be introduced to this roll-fed paper bag making equipment to meet the needs for customers producing window bags, two piles bags, etc.

Optional equipment

Servo window die cutter unit

Servo film patching unit

Servo two layer unit

Bag Production

Carrier bag with

a cord handle

Two-layer block

bottom bag

Block bottom bag

with see-through

window

Block bottom bag

Cut-off handle

block bottom bag

Specification

| Model | SBH290 |

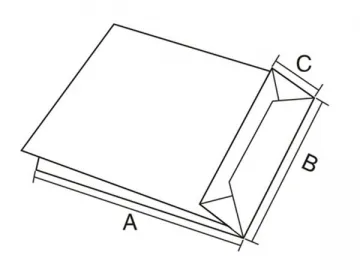

| Material width | 395 to 910mm |

| Cut-off length | 280 to 530mm |

| Bag width | 120 to 290mm |

| Bottom width | 70 to 150mm |

| Paper basis weight | 50 to 150GSM |

| Max. roll diameter | <=1200mm |

| Roll inner diameter | Φ76mm |

| Max. production capacity | 220pcs/min |

| Total power | 15kW |

| Machine weight | About 9000kg |

| Machine dimension | 9600mm × 2800mm × 1800mm |

Scan QR to Read

Links:https://globefindpro.com/products/44552.html

Links:https://globefindpro.com/products/44552.html

Recommended Products

-

ZB1300B Paper Bag Forming Machine

ZB1300B Paper Bag Forming Machine

-

SBH290 Automatic Block Bottom Paper Bag Machine

SBH290 Automatic Block Bottom Paper Bag Machine

-

ZB50B-2 Paper Bag Bottom Gluing Machine

ZB50B-2 Paper Bag Bottom Gluing Machine

-

SBH-PAV02 Servo Patch Unit (Optional)

SBH-PAV02 Servo Patch Unit (Optional)

-

ZB50B Paper Bag Bottom Gluing Machine

ZB50B Paper Bag Bottom Gluing Machine

-

ZB1100A Paper Bag Forming Machine

ZB1100A Paper Bag Forming Machine

-

ZB960C-330 Sheet-Feeding Automatic Paper Bag Making Machine

ZB960C-330 Sheet-Feeding Automatic Paper Bag Making Machine

-

ZB1300B-1 Paper Bag Forming Machine

ZB1300B-1 Paper Bag Forming Machine

-

Envelope Making Machine (Pocket Envelope, model POCKET120)

Envelope Making Machine (Pocket Envelope, model POCKET120)

-

Vibrating Screen

Vibrating Screen

-

Plastic Pipe Shredder

Plastic Pipe Shredder

-

Magnetic Separator

Magnetic Separator

Hot Products