Polymer Make-up and Dosing System

An HBT series thickener works with a gravity belt type thickening process in order to obtain a high solid content treatment effect. Polymer costs are reduced due to the lowered number of flocculants required than a rotary drum thickener, though this machine takes up a slightly larger floor space. It is ideal for sludge treatment when the sludge concentration is below 1%.

Features

Suitable for a variety of sludge types, even when the moisture content within the sludge is 99.6%.

Greater than 96% solid recovery rate

Steady operation with little to no noise

Easy operation and maintenance ensures the long service life.

The sludge thickener perfects the thickening process even when the sludge concentration varies.

There is a 40% larger output capacity than other machines that occupy the same amount of floor space.

Costs for land, construction, operation and labor are lowered due to the smaller space occupation, simple structure, less flocculants required and fully automatic operation.

Components

Our gravity belt sludge thickener comes with superior quality gearmotor, rollers, filtering belt, and robust construction. It is also installed with stainless steel nozzles to clean the belt during operation, which can guarantee the continual performance of the belt thickener. The belt is aligned by the air cylinders automatically during the operation. It is tensioned either by mechanical springs with low investment, or by air cylinders for automatic operation.

Working Principle

The gravity belt sludge thickener depends on the gravity force to remove water from the sludge through a single woven cloth belt. Firstly, the slurry and flocculating polymer are evenly mixed in the conditioning tank. They become solid floc granules that can be easily dewatered after agitation. Then, they flow into the gravity drainage zone.

The flocculated sludge is uniformly distributed on the filtering belt. During the operating of belt, free water is removed from sludge by gravity through a fine mesh of the filtering belt. During the moving of sludge, special plows continuously turn and distribute the sludge across the width of the belt. The residual free water is further eliminated to achieve the sludge thickening process. In this way, the gravity belt sludge thickener allows both processing time and water content rate to be greatly reduced.

After filtration, the solids content of free water ranges from 0.5‰ to 1‰, which is closely related with the types and dosage of the polymer purchased.

Links:https://globefindpro.com/products/44963.html

-

Semi-automatic Stretch Film Slitter Rewinder

Semi-automatic Stretch Film Slitter Rewinder

-

Maize Degerminator

Maize Degerminator

-

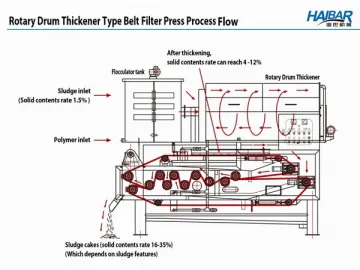

Principle of Drum Thickening-Dewatering Belt Filter Press

Principle of Drum Thickening-Dewatering Belt Filter Press

-

Semi-automatic Aluminum Foil Rewinder

Semi-automatic Aluminum Foil Rewinder

-

Semi-automatic Coreless Film Rewinder

Semi-automatic Coreless Film Rewinder

-

Nonwoven Slitter Rewinder

Nonwoven Slitter Rewinder

-

HTBH Belt Filter Press Combined Rotary Drum Thickener, Standard Type

HTBH Belt Filter Press Combined Rotary Drum Thickener, Standard Type

-

Sludge Dewatering System

Sludge Dewatering System

-

DIN3093 Aluminium Ferrules/Sleeves, Wire Rope

DIN3093 Aluminium Ferrules/Sleeves, Wire Rope

-

Soft Play Equipment

Soft Play Equipment

-

Mini Series Playground

Mini Series Playground

-

Climbing Frame

Climbing Frame