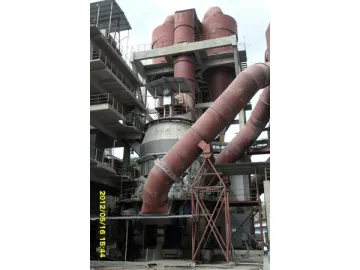

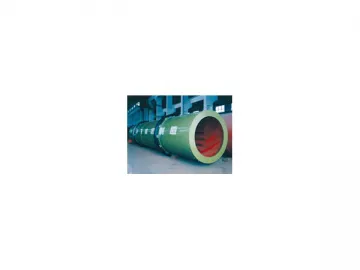

Non-ferrous Metallurgical Industry Rotary Kiln

The non-ferrous metallurgical industry rotary kiln is a large-sized calcination equipment of international advanced level. As compared with conventional products, it can increase production capacity by 30%, and reduce heat consumption by 40%. Its exhaust gas temperature is less than 250℃, making dust collection convenient. So, the machine is environmental friendly.

Features

1. By taking deflection and deflection angle into consideration, the kiln shell comes with optimized structure design. This effectively extends the lifespan of refractory bricks and pouring material.

2. In order to enhance reliability, this range of non-ferrous metallurgical industry rotary kiln is equipped with self-aligned, supporting roller bearings with large diameter and small length-diameter ratio.

3. The new type sealing method for the open gear cover provides superior sealing performance.

4. The kiln adopts a flexible seal system made up of overlapped seal leaves. Double-layer seal leaves offers increased heat insulation and better sealing performance as well as extended service life.

| Size (m) | Φ5.5×115 | Φ5.2×118 | Φ4.85×75 | Φ4.8×110 | Φ4.6×100 | Φ4.4×100 | Φ4.0×90 | Φ3.8×85 | ||

| Production capacity (t/d) | 80-100 | 80-90 | 51-57.5 | 45-60 | 40-50 | 40-45 | 34-38 | 23-26 | ||

| Kiln shell slope (%) | 3.0 | 3.5 | 5.2 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | ||

| Supporter quantity | 4 | 5 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| Thrust roller type | Hydraulic | |||||||||

| Kiln shell rotation speed | Main drive unit (r/min) | 0.2-1.2 | 0.2-1.233 | 0.5-1.04 | 0.5-1.53 | 0.21-1.56 | 0.2-1.206 | 0.2-1.206 | 0.2-1.2 | |

| Auxiliary drive unit (r/min) | 6.7 | 7.82 | 6.59 | 9.9 | 7.85 | 7.93 | 7.93 | 7.9 | ||

| Main drive unit | Electric motor | Model | YTSP400 L1-6 | YSNP450 L1-6 | YPT355 M-6 | YSNP450 L1-6 | YTSP355 L-6 | YPT355 M-6 | YSNP355 M2-6 | YSNP355 M1-6 |

| Rated power (kw) | 315×2 | 355×2 | 200×2 | 355×2 | 250×2 | 200×2 | 160×2 | 132×2 | ||

| Speed range(r/min) | 160-980 | 160-980 | 470-980 | 300-980 | 120-1000 | 470-980 | 470-980 | 470-980 | ||

| Rated voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Speed reducer | Model | P417-90 | P320W-90 | P316W-100 | P318W-80 | ZSY710-63 | ZSY630-63 | P312-71 | P312-71 | |

| Total speed ratio | 90 | 90 | 100 | 80 | 63 | 63 | 71 | 71 | ||

| Auxiliary drive unit | Electric motor | Model | Y200L-4 | Y225S-4 | Y225S-4 | Y225S-4 | Y225S-4 | Y180L-4 | Y180M-4 | Y180M-4 |

| Rated power (kw) | 30×2 | 37×2 | 37×2 | 37×2 | 37×2 | 22×2 | 18.5 | 18.5 | ||

| Rated speed (r/min) | 1480 | 1480 | 1480 | 1480 | 1480 | 1480 | 1480 | 1480 | ||

| Rated voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Speed reducer | Model | YNL340-16 | YNL305-14 | YNL305-14 | YNL305-14 | ZLY224-20 | ZLY180-18 | ZLY180-18 | ZLY180-18 | |

| Total speed ratio | 16 | 14 | 14 | 14 | 20 | 18 | 18 | 18 | ||

| Weight (excluding refractory bricks) (t) | 1675 | 1650 | 1160 | 1320 | 1060 | 912 | 756 | 705 | ||

Note: Above technical specifications are provided for your reference only. Detailed ones are provided in contracts.

Related Names

Non-ferrous Metal Equipment | Large Refractory Kiln | Heat Insulated Kiln

Links:https://globefindpro.com/products/45323.html

-

Kaolin Rotary Kiln, Bauxite Calciner, Zinc Oxide Calciner

Kaolin Rotary Kiln, Bauxite Calciner, Zinc Oxide Calciner

-

Vertical Raw Mill

Vertical Raw Mill

-

Jaw Crusher

Jaw Crusher

-

Air Swept Coal Mill

Air Swept Coal Mill

-

Rotary Dryer

Rotary Dryer

-

Cone Crusher

Cone Crusher

-

1500 Ton Cement Processing Line

1500 Ton Cement Processing Line

-

Vertical Pre-Grinding Mill

Vertical Pre-Grinding Mill

-

Cement Grinding Mill

Cement Grinding Mill

-

2500 Ton Dry Process Cement Plant

2500 Ton Dry Process Cement Plant

-

Material Feed Weigher

Material Feed Weigher

-

Lubrication System and Mill Control Cabinet

Lubrication System and Mill Control Cabinet