Chick Takeoff Equipment

Chick Takeoff Equipment

With the increase of labor costsnowadays in China and the rapidly developed advanced technology, artificialhatchery is gradually out of date simply because of its inefficiency, poorprecision and insanitary.Therefore, the need to adopt automated systems is urgent, much more than everbefore.

Being committed to innovation and the strategy of holding the independentintellectual property rights to key technologies and products, Qingdao Xingyi Co. Ltd has successfully launched its EIautomated equipment after countless trial and error and a series of technologyresearch. Now our company is engaged in providing automated, intelligent andeconomical equipment for large and medium sized hatcheries within the country.

Chick takeoff, countingand packaging equipment is the core factor of the automated assembly line inlarge and medium sized hatcheries. It is responsible for short distancedelivery, gender identification, selection of healthy chicks, sorting andpackaging, etc. The equipment can be randomly combined from the chick-pickingtable, eggshell crusher, spiral conveyor, belt conveyor and washing machine.Plus, a differentiated chicktakeoff assembly line is to initiate according to the different requirements ofour customers.

The application anddevelopment prospect

From thedisease prevention point of view, the chick takeoff equipment is the inevitabletrend in that it helps to control the microbiological environment. As a result,the working stuff has less direct contact with the eggs which ensures thehygiene working environment. In addition, our company now is working to extendthe various existing functions, for example the combination of the sorting andcounting packaging equipment with the automatically inverted plate and washingmachine so that the realization of automatic dumping, the egg-shell separationand other functions can be achieved. With these expanded functions, fullautomation is easy to fulfill.

Workflow of the modernautomated incubators

The operators first pull the hatchingtrolleys from the hatching machine and take the trolleys to a certain fixedlocation so that they can be detected by the equipment. Then, the robot handstake out the hatching trays automatically from the trolleys to the conveyorbelt to separate the embryos, eggshells and hatching trays by an automaticchick-shell separator. The separator then automatically turns into twooperating ways. One way takes the empty hatching trays to the cleaning devicefor automatic washing, and the other separates the chicks and the eggshells.The separated eggshells afterwards will be sent to the grinder and then to thetrash room through a spiral conveyor. The chicks, on the other hand, will betransported to the counting device for classification, gender identification,vaccination and final packing.

Links:https://globefindpro.com/products/46812.html

-

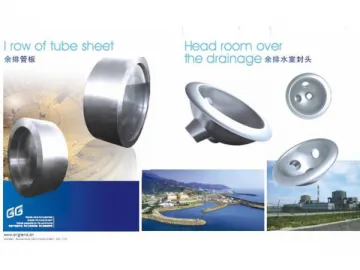

Forged Part Manufacturer

Forged Part Manufacturer

-

Single Stage Incubator

Single Stage Incubator

-

Telescopic Crane Loader, 3T Crane Telehandler

Telescopic Crane Loader, 3T Crane Telehandler

-

Calendering Machine

Calendering Machine

-

Creasing Chamfering Slotting Machine

Creasing Chamfering Slotting Machine

-

Thin Blade Slitter Machine

Thin Blade Slitter Machine

-

Container Diesel Forklift Truck

Container Diesel Forklift Truck

-

Stone Diesel Forklift Truck

Stone Diesel Forklift Truck

-

Calendering Machine Roll

Calendering Machine Roll

-

1310nm Pulse Laser Module for OTDR

1310nm Pulse Laser Module for OTDR

-

Nuclear Power Forged Parts R&D

Nuclear Power Forged Parts R&D

-

Wind Power Turbine Shaft

Wind Power Turbine Shaft