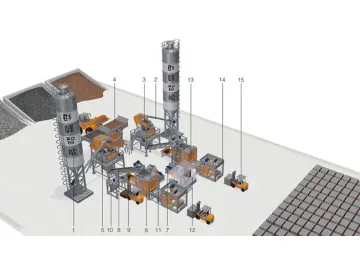

Double Block Making Production Line

The making production line includes batching, automatic mixing, automatic molding/block producing, stacking, and forklift transferring. It requires nine workers.

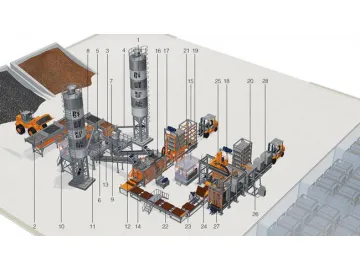

Double Block Production Line 1.Cement Silo 2.Screw Conveyor 3.Cement Scale 4.Batching Machine 5.Concrete Mixer 6.Block Making Machine 7.Hydraulic Unit 8.Conveyer Belt 9.Pallets Feeder 10. Automatic Pallet Provider 11.Block Conveyer 12.Control Room 13.Mould 14.Blocks Stacker 15.Forklift Concrete Blocks made by the machine QFK-1 390x140x190mm concrete hollow block QFK-2 390x140x190mm concrete hollow block QFK-3 390x140x190mm concrete hollow block QFK-4 390x140x190mm concrete hollow block QFK-5 390x140x190mm hollow concrete block QFK-6 190x190x190mm hollow concrete block| Base Production Line | ||

| No. | Name | Model |

| 1 | Compulsion Type Concrete Mixer | JS750 |

| 2 | Block Making Machine | |

| 3 | Hydraulic Unit | Included |

| 4 | Conveyor Belt I | Included |

| 5 | Pallets Feeder | Included |

| 6 | Blocks Conveyor | Included |

| 7 | PLC Control Unit | Included |

| 8 | Mould | Included |

| 9 | Auto. Color Feeding System | |

| 10 | Conveyor Belt II | |

| 11 | Pigment Mixer | JQM500 |

| 12 | Blocks Stacker | |

| 13 | Manual Hydraulic Forklift | |

| 14 | Bamboo Pallets | 1100×680×25mm |

| Note:: | ||

| 1. If the customer doesn't produce colored layered paving stone, the Auto Color Feeding System (No.13-15) can be deducted. 2. All kinds of molds can be produced per the customer's drawings. | ||

Qunfeng is a professional concrete block production line manufacturer, based in China. We also provide concrete block splitter, concrete mixer, roof tile forming machine, paving stone machine, and more.

Index

concrete block machine, brick making machine, construction block, interlocking paver brick

Scan QR to Read

Links:https://globefindpro.com/products/47634.html

Links:https://globefindpro.com/products/47634.html

Recommended Products

-

Concrete Mixer JQM500

Concrete Mixer JQM500

-

Compulsion Concrete Mixer, JS Series

Compulsion Concrete Mixer, JS Series

-

Block Production Line With Curing Room

Block Production Line With Curing Room

-

Fully Automatic Block Production Line With Curing Rack

Fully Automatic Block Production Line With Curing Rack

-

Concrete Mixer JQ500

Concrete Mixer JQ500

-

Block Making Machine QF1300

Block Making Machine QF1300

-

Concrete Batch Plant

Concrete Batch Plant

-

Concrete Batching Machine PL1600

Concrete Batching Machine PL1600

-

Block Making Machine QF800

Block Making Machine QF800

-

Block Mould

Block Mould

-

Refuse Transfer Station

Refuse Transfer Station

-

Concrete Block Splitter

Concrete Block Splitter

Hot Products