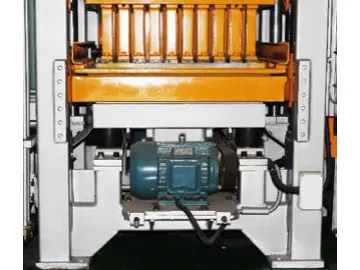

Block Making Machine QFT18-20(300)

Block Making Machine QFT18-20(300)

Block Making Machine QFT18-20(300)

Description

The block making machine QFT18-20(300) (18 stands for the productionquantity of 18 blocks “400x200x200mm”per mold, 20 stands for the cycle time of 20 seconds) has the production outputof 25,920 blocks (400x200x200mm)or 360 cubic meters for one day (8 working hours). As the molds are changeable,the block making machine is able to produce different types of blocks/bricks. The QFT18-20(300) block making machine is the largestcapacity machine in the world. You can make different designs of concreteblocks, bricks, paving stone and curbstone by simply changing the molds. Themaximum heightof products produced by this machine is 300mm.

Features

1. The block making machine uses Germany Siemens PLCcontrol system and Siemens Touch Screen.

a. It has a human-computer interfacescreen with easy operation.

b. It is able to set up, update andamend the production perimeters to maximize the production output.

c. It offers a dynamic display of thesystem’s status, automatic trouble shooting and warning notice.

d. It has an advanced logical safetylock function, avoiding mechanical accidents caused by operational mistakes.

e. It is able to troubleshoot themachinery via remote control.

2. It uses proportional electrical and hydraulic control reliefvalves, which automatically adjust the oil flow and pressure as per specificworking requirements, to buffer the hydraulic cylinder when working. It usesintegrated high-pressure and soft oil pipes, with easy installation.

3. It offers optimum structure of vibrating shafts, which assure thevibration is distributed uniformly in the range of the vibrating table, therebyimproving the uniformity and stability of blocks, produces better quality ofproduct than before when using the same ratio of raw material, and effectivelyreduces the noise.

4.The block making machine uses a special designof fixing table and knock type vibration, improves the speed of making productand the accuracy of the size of product.

5. It uses multi-shaft rotating and compulsory feeding, which greatlyimproves the density and intensity of the blocks, and reduces the feeding time.

6. It has a heavy-duty machine frame, which uses high-intensity steeland advanced heat treatment. It is wear resistant.

7. Themold frame is made with inlaid structure, and the mold is processed via theprocedures of carburizing, nitriding and quenching which guarantee that thestrength of mold core and mold surface could be HRC52-HRC62.

8. The lifespan of mold is not less than100 thousandtimes.

Technical Parameters of the BlockMaking Machine QFT18-20(300)

| Mainframe Dimension | 4950x2950x4750mm |

| Vibration | Table vibration |

| Pallet size | 1400x1300mm |

| Power | 85kw |

| Rating pressure | 21MPa |

| Vibration frequency | 2800-4500r/min |

| Cycle time | 15-25sec. |

| Weight | 250000kg |

Capacity

| Items | Size (LxWxH) | Pcs./mold | Pcs./hour | Pcs./8 hours | One Year (300days) Production |

| Blocks | 390x190x190mm | 18 | 3,240 | 25,920 | 7,776,000 |

| Porous Bricks | 240x115x90mm | 50 | 12,000 | 96,000 | 28,800,000 |

| Solid Bricks | 240x115x53mm | 95 | 22,800 | 182,400 | 54,720,000 |

| Holland Bricks | 200x100x60mm | 60 | 8,640 | 69,120 | 20,736,000 |

Established in Chinain 1993, Qunfeng is a block making machine manufacturer and supplier. Ourcompany provides a vast range of products that include our fully automaticblock making production line, roof tile forming machine, concrete batchingmachine, concrete curb machine, refuse transfer station, and others.

Links:https://globefindpro.com/products/47646.html

-

Block Making Machine QF400

Block Making Machine QF400

-

Spray Granulation Dryer

Spray Granulation Dryer

-

Pan Mixer

Pan Mixer

-

Rotary Dryer

Rotary Dryer

-

BB Fertilizer Equipment

BB Fertilizer Equipment

-

Organic Fertilizer Equipment

Organic Fertilizer Equipment

-

Block Making Machine QF1300(300)

Block Making Machine QF1300(300)

-

Block Making Machine QF1300

Block Making Machine QF1300

-

Concrete Mixer JQ500

Concrete Mixer JQ500

-

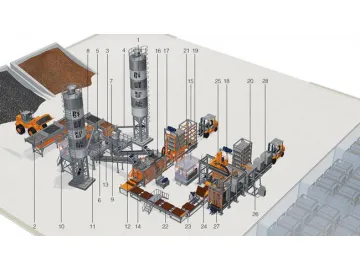

Fully Automatic Block Production Line With Curing Rack

Fully Automatic Block Production Line With Curing Rack

-

Block Production Line With Curing Room

Block Production Line With Curing Room

-

Compulsion Concrete Mixer, JS Series

Compulsion Concrete Mixer, JS Series