Industrial Cable Manufacturer

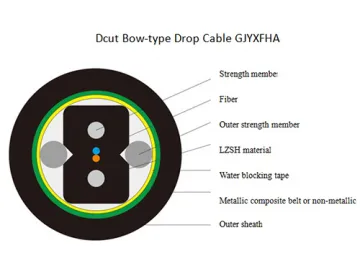

Description of GJYX (F) HA fiber, duct bow type drop cable  Application

Application

Characteristic of optical fiber

Main machinery and environment performance

Features

There is no gel used in this optical cable, making it lightweight and easy to install or connect. The metal tube is located at the access port and connection point, and will protect the optical cable from breaking when it is used. Composite aluminum-plastic tape & water-blocking yarn will efficiently protect the optical fiber in humid environments. Our optical cable is water and moisture resistant. This product is resistant to rodent interference. A strengthened PE material sheath is stronger and more wear resistant than a general cable. The transmission performance will not be affected by bad environmental conditions.

The GJYX (F) HA fiber, duct bow type drop cable is easy to install and connect, and features a water/damp resistance, high insulation, and wear resistance and is exceptionally strong. Strengthened PE material sheathes are generally stronger and more wear resistant than general cables, and the sheath will protect the optical fiber by reducing negative effects from the surrounding environment. The transmission performance thereby remains unaffected by bad environmental conditions.

This product is mainly used in pipeline construction and is suitable for low-density and loose users.

Parameter Technical parameter| Item | Content | Value | |

| Number of cores | 6 | 12 | |

| Strength member | Material | FRP/KFRP | |

| Outer sheath | Thickness /mm | ≥0.3 | |

| Outer strength member | Material | FRP/ Steel wire | |

| Inner sheath | Material | Water-blocking tape | |

| Material | Metal composite tape | ||

| Outer sheath | Material | PE | |

| Reference outer diameter | mm | 12.0 | 12.5 |

| Operating temperature | ℃ | -40~+60 | |

| Tensile force | Short term/long termN | 600/300 | |

| Flatten | Short term/long termN | 2200/1000 | |

| *We can design the structure of optical cable and quantity of cores according to customer requirements. | |||

| G.652.D | G.657A2 | 50/125μm | 62.5/125μm | ||

| Attenuation | @850nm | - | - | ≤3.0dB/km | ≤3.0dB/km |

| @1300nm | - | - | ≤1.0dB/km | ≤1.0dB/km | |

| @1310nm | ≤0.36dB/km | ≤0.36dB/km | - | - | |

| @1550nm | ≤0.22dB/km | ≤0.23dB/km | - | - | |

| Bandwidth | @850nm | - | - | ≥500MHz·km | ≥200MHz·km |

| @1300nm | - | - | ≥1000MHz·km | ≥600MHz·km | |

| Fiber cutoff wavelength | ≤1260nm | ≤1260nm | - | - | |

| Polarization mode dispersion | Single optical fiber | ≤0.20ps/√km | ≤0.20ps/√km | - | - |

| Link value (M=20, Q=0.01%) | ≤0.10ps/√km | - | - | ||

| Item | Inspection standard | Procedure of inspection | Requirements |

| Pull | IEC 60794-1-2-E1 | According to technical parameter | Residual additional attenuation≤0.03dB |

| Flatten | IEC 60794-1-2-E3 | According to technical parameter | Additional attenuation for long term≤0.4dB |

| Impact | IEC 60794-1-2-E4 | Impact: 1N, height: 1m, 3 points at least | Residual additional attenuation≤0.4dB |

| Backward and forward bending | IEC 60794-1-2-E6 | Load: 20N 300times | Residual additional attenuation≤0.4dB |

| Temperature recycle test | IEC 60794-1-2-F1 | -40℃ ~+60℃ | Additional attenuation≤0.02dB |

| Combustion performance | IEC 60332-1-2 | Fire resistance | Every single wire can be burnt vertically. |

| Density of the smoke | Light transmittance ≥50% | ||

| Corrosiveness | PH of the gas when burning≤4.3, electric conductivity≤10μs/mm | ||

| * The monitoring of all optical fiber attenuation changes is operated in wavelength of 1550nm. | |||

There is no gel used in this optical cable, making it lightweight and easy to install or connect. The metal tube is located at the access port and connection point, and will protect the optical cable from breaking when it is used. Composite aluminum-plastic tape & water-blocking yarn will efficiently protect the optical fiber in humid environments. Our optical cable is water and moisture resistant. This product is resistant to rodent interference. A strengthened PE material sheath is stronger and more wear resistant than a general cable. The transmission performance will not be affected by bad environmental conditions.

Scan QR to Read

Links:https://globefindpro.com/products/49024.html

Links:https://globefindpro.com/products/49024.html

Recommended Products

-

LA LB Digital Security Safe

LA LB Digital Security Safe

-

Key Storage Safe

Key Storage Safe

-

Used in Medical Clinic

Used in Medical Clinic

-

Nd:YAG laser

Nd:YAG laser

-

LA LB LC Digital Security Safe

LA LB LC Digital Security Safe

-

EF Electronic Lock Security Safe

EF Electronic Lock Security Safe

-

Patents

Patents

-

Office Lighting

Office Lighting

-

D860 12V 6mm Flexible Advertising LED Strip Light

D860 12V 6mm Flexible Advertising LED Strip Light

-

D6300 12V 8mm Flexible LED Strip Light

D6300 12V 8mm Flexible LED Strip Light

-

TV Set Part Enclosure Mold

TV Set Part Enclosure Mold

-

DJ124 12V 10mm Commercial LED Light Strip

DJ124 12V 10mm Commercial LED Light Strip