Agitator Bead Mill, NT-V

Grinding Chamber Volume: 6L-400L

Fineness: 100nm-2μm

Solvent: water-based, oil-based

Viscosity: ≤10,000cps

Grinding bead size: 0.2-2.0mm or 0.3-2.0mm

Selectable materials: tungsten carbide, polyurethane, zirconium oxide, silicon carbide

Description

NT-V agitator bead mill is a high efficiency wet grinding system used for milling of solid powders into nanometer range particles of a fineness range 100nm-2μm. It allows a higher throughput than that of similar grinding equipment by 30-50%, and the energy consumption is lowered by 30-50%.

Highly efficient centrifugal separation system makes it possible to use grinding media of 0.2-2.0mm. The grinding media is moved in a radial direction by means of rotor, creating shearing and impacting forces on products. Under the shearing and impact action of the grinding beads in grinding chamber, the final particles are finely ground and dispersed.

The design of grinding process aims at offering excellent particle size reduction to a range of 100nm-2μm within a short period. This agitator bead mill is characterized by high efficiency while providing uniform fineness, as well as features including low energy consumption, high stability, and less production and maintenance cost.

Features

Material flows into grinding chamber from inlet;

Add grinding media, such as zirconium oxide grinding beads;

Grinding discs or rotor rotates at a high speed;

Shearing force is produced through the impact action of grinding media, thus to accomplish mixing and dispersing;

Separation system allows the final particles to be discharged out while the grinding beads are retained in grinding chamber;

High efficiency is guaranteed due to the extremely narrow size grinding with high speed of 8-14m/s, thus to provide uniform particle size distribution.

Specifications

| Model | Grinding Chamber Volume (L) | Drive Motor (kW) | Batch Capacity ( L/H) | Media Size (mm) | Weight (kg) | Dimension (mm) |

| NT-V6 | 6 | 15 | 20-100 | 0.2-2.0 | approx. 500 | 1300x710x1600 |

| NT-V10 | 10 | 22 | 30-300 | 0.2-2.0 | approx. 1280 | 1430x860x1780 |

| NT-V25 | 25 | 37/45 | 80-800 | 0.2-2.0 | approx. 1600 | 1830x1050x1950 |

| NT-V30 | 30 | 37/45 | 100-1000 | 0.2-2.0 | approx. 1800 | 1830x1050x1950 |

| NT-V60 | 60 | 75 | 200-2000 | 0.2-2.0 | approx. 3480 | 2230x1050x2200 |

| NT-V100 | 100 | 110/132 | 500-4000 | 0.3-2.0 | approx. 5200 | 2900x1400x2600 |

| NT-V150 | 150 | 160/200 | 800-6000 | 0.3-2.0 | approx. 6600 | 2900x1400x2600 |

| NT-V400 | 400 | 355/400 | 2000-10000 | 0.3-2.0 | approx. 11000 | 3000x1600x2850 |

Optional

Tungsten Carbide

Polyurethane

Zirconium Oxide

Silicon Carbide

A selection of materials including tungsten carbide, zirconium oxide, and silicon carbide are available, which are suited to water-based and oil-based materials for a better corrosion resistance. E.g. zirconium oxide is resistant to acid and alkali, while the polyurethane is more suitable for water-based materials.

Applications

Nano Materials

Graphite

Magnetic Materials

Ceramics

Cosmetics

Lithium Iron Phosphate(LFP)

Inkjet Ink

Medicine

Aluminium Oxide Powder

Insulation Coatings

Nano Silicon

Ceramic Ink

Biological Materials

Zirconium Silicate

Pesticides

Links:https://globefindpro.com/products/4973.html

-

Vacuum Deaerator, LTP

Vacuum Deaerator, LTP

-

Components

Components

-

Planetary Mixing Machine, XJ

Planetary Mixing Machine, XJ

-

Pharma & Cosmetics

Pharma & Cosmetics

-

Mixing Tank

Mixing Tank

-

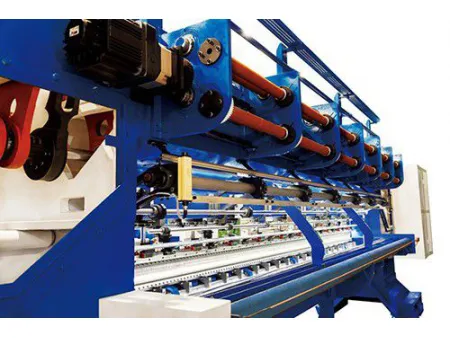

Carpet Tufting Machine

Carpet Tufting Machine

-

Pigments / Dyes

Pigments / Dyes

-

LH5 CNC Horizontal Wire Foam Cutting Machine

LH5 CNC Horizontal Wire Foam Cutting Machine

-

Carpet Tufting Machine

Carpet Tufting Machine

-

Carpet Tufting Machine, with Double Sliding Needle Bar

Carpet Tufting Machine, with Double Sliding Needle Bar

-

Multi-color Carpet Tufting Machine, COLORDOT

Multi-color Carpet Tufting Machine, COLORDOT

-

Agitator Bead Mill, LSM

Agitator Bead Mill, LSM