Spring Strips

Spring strips are typically made of Martensitic steel or stainless steel such as 62Si2MnA, 65Mn, BTX(1078) steel. The metal spring strips are widely used for stamping parts and elastic elements which require strong hardness, high strength and high elasticity. Zongda is equipped with advanced heat treatment facilities and updated the spring strip production process based on 25 years of industry experience, greatly improving the quality of the springs. The hardness and toughness of spring strips can be precisely controlled by adjusting the heat treatment conditions based on the needs of customers to make different strips with various characteristics. For instance, the temperature during heating process only has an error of +1℃ and the hardness of heat treatment is normally controlled within HV+10.

The facilities of heat treatment in Zongda can meet the production requirements. Our spring strips are processed using mature and environmental friendly water quenching instead of oil quenching. Spring strips are cooled by graphite to achieve a more reliable quality. The spring strips made by Zongda have a thickness range of 0.15-2.3mm, width of less than 200mm and the sizes can be changed based on customer needs.

Links:https://globefindpro.com/products/49816.html

-

TL-D3100K Filmmaking 31 Inch LCD Monitor

TL-D3100K Filmmaking 31 Inch LCD Monitor

-

Molded Plastic Components

Molded Plastic Components

-

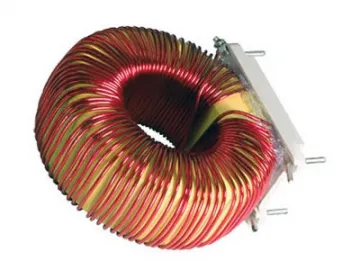

Toroid Coils

Toroid Coils

-

TL-B2400HD Desktop 23.8 Inch Broadcast Monitor, LCD Monitor

TL-B2400HD Desktop 23.8 Inch Broadcast Monitor, LCD Monitor

-

TL-P2150HD 21.5 Inch Carry-On Monitor, LCD Monitor

TL-P2150HD 21.5 Inch Carry-On Monitor, LCD Monitor

-

Elastic Support

Elastic Support

-

TLP800HD-2 Professional Rackmount 8 Inch Color Monitor, LCD Monitor

TLP800HD-2 Professional Rackmount 8 Inch Color Monitor, LCD Monitor

-

Jib Monitor

Jib Monitor

-

TL-S1851HD Professional Desktop 18.5 Inch Monitor, LCD Monitor

TL-S1851HD Professional Desktop 18.5 Inch Monitor, LCD Monitor

-

HL-700HD 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

HL-700HD 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

-

HL-700HDM 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

HL-700HDM 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

-

Plastic Core Coil

Plastic Core Coil