Other Assembly and Aging Lines

Aging Line for Street Lights, LCD Circular Assembly Line, Aging Line for Electric Motorcycle Charger

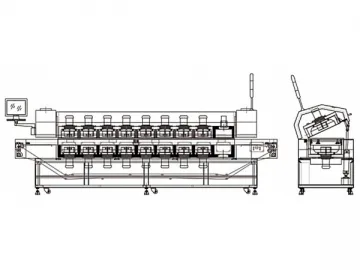

LED Street Light Aging Line, 15 Meters

Brief Introduction

This aging line is specially manufactured for the automatic inspection of LED street lights. Installed with 7-inch display, Mitsubishi PLC, large-power voltage regulator and powerful power output, this LED street light aging line is applicable for any type of LED street light on the earth.

Main Parts

Drive System (1 Set)

1. 1.5 kW motor, 1: 100 gear box.

2. 0-2 meters/ minute speed, 2HP frequency changer.

Main Body (30 Meters)

1. The main structure of machine implements 50× 50× 2 mm rectangular steel tubes. The work table is 1200±20 mm high.

2. On both ends of the LED street light aging line, the protective board is produced from 1.5mm cold-rolled plates.

3. Conduction system is installed on both sides of the LED lights aging line.

Electric Control System (1 Set)

1. The aging line utilizes high quality chains and has a total length of 30 meters.

2. Digital-display voltage meter, PLC, 7-inch touch screen and 6 voltage regulators are used.

3. A power distribution cabinet is installed.

4. An Emergency switch is designed in order for high working security.

Worktable (43 Set)

1. Dimensions (L×W×H): 1000mm × 500mm ×465 mm

2. Each worktable is equipped with 12 clamps for wire holders. (Red: Positive pole. Black: Negative pole)

3. Each worktable is capable to handle 2 LED street lights at the same time.

4. On the side of worktable, copper brush is mounted and used in the conduction system. Small-size breakers are used to protect the circuit.

5. The standard aging line is manufactured with 43 worktables. If you are not satisfied with such design, we also offer custom-made LED street light aging line.

Circuit Testing System (1 Set)

1. Aging control zone

2. Digital-display relay, adjustable voltage output.

Voltage Regulating System (1 Set)

1. The entire aging line is installed with 6 AC/30kW regulators in 6 zones. The regulator is adjustable within 0-300V and designed with a power supply of 0-96V DC and 600A current.

2. The standard parameters are AC/160kW/220V. The actual energy consumption depends on the quantity of LED lights.

Main Parts

Drive System (13 Sets)

1. YongKun 3HP horizontal motor, 1: 120 gearbox

2. Working speed: 6 meters per minute

3. RF2060 high speed chain

Bottom Structure (53 Meters)

1. The structure is produced from 50mm×50mm×2.0mm steel square tubes. The work table is 740±20mm high.

2. 100×118mm aluminum material is used on both sides.

3. T5 18W LED tubes are applied for lighting. The light bracket is produced from 20×40 mm steel tubes.

4. The power system is installed with a socket every 1.2 meters.

5. The electrical rails are 3-row designed and installed with a conductive caster every 200 mm.

6. 40SM and 20PH connectors are implemented.

7. The working board makes used of aluminum material and A4 acrylic board.

8. 28×35 mm aluminum material is applied in the groove.

Super Structure (184 Meters)

1. The support makes use of 50mm× 50mm× 2.0mm steel square tubes.

2. Both sides of the assembly line utilize high strength 100× 118 mm aluminum material is used.

3. The wire duct implements 1.5 mm thick cold-rolled plates.

4. The electrical rails are 3-row designed and installed with a conductive caster every 200 mm.

5. A conductive groove is installed in the middle.

Testing Line

1. The testing line makes use of 50mm× 50mm steel square tubes. The height of work table is 750±20 mm.

2. Both sides of the assembly line utilize high strength 100× 118 mm aluminum material is used.

3. The wire duct is made from 1.5 mm thick cold-rolled plates.

4. The electrical rails are 3-row designed and installed with a conductive caster every 200 mm.

Packaging Section (6 Meters)

1. YongKun 1HP motor, 1: 60 gearbox

2. Speed: 0-6 meters/minute, Adlee 1HP frequency changer

3. The working section is made using 40×40 mm square tubes, with a height of 750±20mm

4. The beams are produced from 40×60 mm aluminum.

5. The transmission system consists of 2mm×1000PVC anti-static belts, ¢25×1000 galvanized drum and protective galvanized plates.

Maintenance Device (2 Sets)

1. The maintenance device is 1300 mm long, 956mm wide and 780 mm high. The support is made from 40×40 steel square tubes.

2. The aluminum frame is installed with two 2″ brakes.

Hanging Bracket (16 Pieces)

The whole bracket is 4000 mm long, made from 1〞 galvanized tubes and 40×75 mm tubes, and connected with M16 screws.

Protective Rail (92 Meters)

30×30 mm steel square tube is used to realize high strength. In consideration of anti-rust, yellow coating is covered.

Maintenance Lane (64 Meters)

The lane is welded from 30×30 mm steel square tube and covered with 2mm anti-slip white painting.

Electric Box (1 set)

1. Mitsubishi PLC

2. Mitsubishi air switch

3. OMRON relay

Worktable (300 sets)

1. Dimensions (L ×W×T): 750mm× 900 mm × 20mm.

2. The worktable is covered with 2mm anti-static rubber and T-shape bonding tape.

3. Other accessories include: multiple outlets, two-port switch, fire-proof boards and conductive copper bars.

DY-1 Barrier (52 Sets)

Each DY-1 barrier is controlled by a foot switch.

Horizontal Barrier (16 Sets)

High quality horizontal barrier works well with the foot switch.

Horizontal Truck (2 Sets)

The moveable truck is composed of 400W motor, 60W gearbox frequency changer and anti-slip belt.

Vertical Truck (7 Sets)

This truck applies DPG 60 W gearbox, 60W motor and OMRON limit switch, allowing for smooth transfer in the vertical direction.

Hoisting Device (2 Sets)

1. Anti-slip belt matches well with 60 W gearbox, realizing stable operation.

2. High rigid chains and 0.4 kW motor both control the hoisting work.

3. Polymethyl methacrylate and aluminum are used.

Outstanding Advantages

1. This aging line is appropriate for electric motorcycle chargers of different models.

2. In-line testing system is applied.

3. The electric motorcycle charger aging line adopts chain transmission and offers large-power resistance testing.

4. It's also equipped with an excellent conductive device and low-noise cooling device.

Main Parts

Drive System (1 Set)

1. Both ends are designed with charger discharge area.

2. The working time is adjustable between 30-40 minutes. YongKun 2Hp horizontal motor is used for frequency control.

Aging Line (18 Meters)

1. The charge aging line is 18 meters long, of which 16 meters are effective working length. It’s 1350 mm wide and 750±20mm high.

2. The aging line consists of normal-temperature aging zone A (1 meter), high-temperature aging zone (15 meters) and normal-temperature aging zone B (1 meter).

Conductive System

The system implements copper brush and stainless steel rails, both of which are protected by insulating materials.

Worktable (230 Pieces)

1. Produced from 2mm cold-rolled steel plates, the worktable board is 1250mm long and 146 mm wide. It's covered with black painting.

2. Every work table handles 2 charges.

3. A 1P 6A breaker is mounted on every worktable for circuit protection.

4. The worktable can be designed upon request.

Temperature Control

1. High-temperature zone is designed with good quality heating tubes, with a total heating power of 10 kW.

2. The high-temperature aging zone is covered with 50 mm thick rock wool board, which provides a strong guarantee of temperature and saves energy at the same time.

3. The temperature is controlled by three temperature control meters and exhaust system, leading to stable temperature.

Electric Cabinet

The cabinet is installed with temperature controller, frequency changer and more. Its total power is about 15 kW.

Surface Processing

The entire aging line is made using 40mm×40mm×1.5mm high quality square tubes and cold-rolled plates, covered with white coating.

Links:https://globefindpro.com/products/53498.html

-

PCB Turn Conveyor

PCB Turn Conveyor

-

PCB Workstation Belt Conveyor (less than 10 meters)

PCB Workstation Belt Conveyor (less than 10 meters)

-

Lead Free Reflow Oven, GSD-M6N

Lead Free Reflow Oven, GSD-M6N

-

PCB Magazine Unloader

PCB Magazine Unloader

-

Lead Free Reflow Oven, GSD-M6C

Lead Free Reflow Oven, GSD-M6C

-

Reflow Oven, GSD-S6C

Reflow Oven, GSD-S6C

-

Reflow Oven, GSD-S8C

Reflow Oven, GSD-S8C

-

Chip Mounter, GSD-TP1200

Chip Mounter, GSD-TP1200

-

Lead Free Reflow Oven, GSD-M8N

Lead Free Reflow Oven, GSD-M8N

-

Lead Free Reflow Oven, GSD-M8C

Lead Free Reflow Oven, GSD-M8C

-

Wave Soldering Machine, GSD-WD350C

Wave Soldering Machine, GSD-WD350C

-

Manual Cutting Machine

Manual Cutting Machine