Stainless Steel Slitting Line

Strip Processing Equipment, Stainless Steel Slitter, Strip Cutting Line

Technologically developed, this slitting machine is superiorly used for cutting and slitting stainless steels of a particular width so that they can be used in the manufacture of other types of finished products, such as metal stamping, roll forming and tube producing. Today, a great number of pipe and tube producers make stainless steel coils and parts while using Bangzhou coil handling machinery. Well-respected reputation has been built in the metal industry.

Outstanding Advantages of Strip Processing Equipment

1. The automatic system makes the operation easy and labor saving.

2. Stable and consistent performance ensures every minute of your time is productive.

3. Top quality DC motors lead to the smooth running of the machine.

Technical Parameters of Stainless Steel Slitter

| Process material | Stainless steel |

| Thickness of coiled plate | 0.3-3mm |

| Width of coiled plate | 1600mm |

| Width tolerance | ±0.05mm/2M |

| Slitting speed | 0-120m/min |

| Loading capacity | 15T |

| Coil inner dia. | 480-510mm |

| Coil outer dia. | ≤1800mm |

| Dia. of slitting blade | 200mm |

| Specifications of slitting blade | 200mm×340mm×20mm |

| Material of slitting blade | LD |

| Hardness of blade | HRC58°-60° |

| Recoiler inner dia. | 508mm |

| Power | 380V three-phase 50Hz |

| Size | 25mx8m |

Main Parts of Strip Cutting Line

1. Coil car; 2. Decoiler; 3. Hydraulic guiding, pressing, pinching and pre-leveling device; 4. Head-cutting machine; 5. Conveyor table I; 6. Slitting machine; 7. Scrap winder; 8. Conveyor table II; 9. Tension stand---damping device for pre-dividing and pressing; 10. Recoiler; 11. Discharge car; 12. Electrical control system; 13. Hydraulic system

Recoiler

Decoiler

Hydraulic guiding, pressing, pinching and pre-leveling device

Slitting machine

Tension stand---damping device for pre-dividing and pressing

Packaging & Shipping

1. Processing machines will be bare, all rolling components will undergo anti-rust treatment and the other parts will be placed into steel boxes.

2. Delivery: 100 days

3. Container: 1 x 40 OT and 2 x 40GP

4. All parts in the containers will be placed and fastened tightly in case of potential damages.

Links:https://globefindpro.com/products/53998.html

-

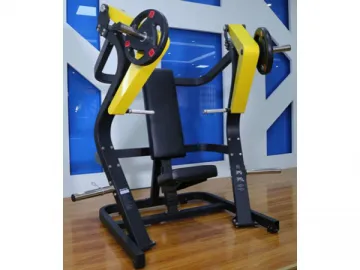

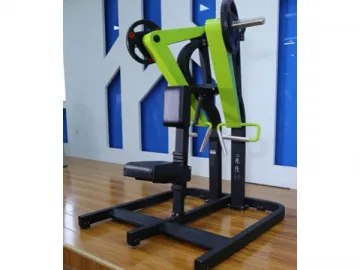

Plate Loaded Machine

Plate Loaded Machine

-

Functional Training Rig 360S

Functional Training Rig 360S

-

Hot Rolled Steel Slitting Line

Hot Rolled Steel Slitting Line

-

Functional Training Rig 360XL

Functional Training Rig 360XL

-

Shoulder Press AXD-5006

Shoulder Press AXD-5006

-

Functional Training Rig 360XM

Functional Training Rig 360XM

-

Commercial Treadmill AXD-6900

Commercial Treadmill AXD-6900

-

Functional Training Rig 360T

Functional Training Rig 360T

-

Low Row Machine AXD-725

Low Row Machine AXD-725

-

Spinning Bike

Spinning Bike

-

Functional Training Rig 360XS

Functional Training Rig 360XS

-

Functional Training Rigs

Functional Training Rigs