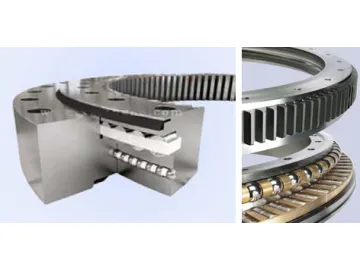

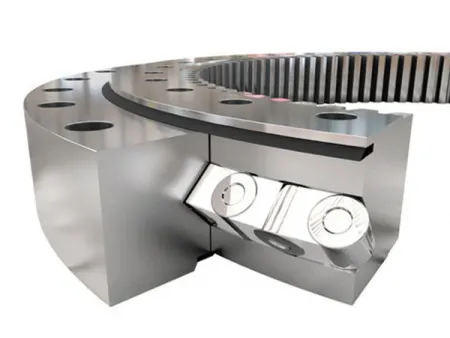

Double-row Ball Slewing Ring Bearing

Double-row ball slewing ring with same diameter balls is usually used for wind driven generators and concrete pump trucks. In wind driven generator applications, double-row ball slewing ring is often installed at the bottom of propellers for variable pitch control which requires zero clearance, large start friction moment and high running accuracy.

Outer diameter: 704mm~4395mm

Ball diameter: 25mm~60mm

With compact construction, the double-row ball slewing ring bearing decreases the diameter of mounting holes in the inner and outer ring and increases the loading capacity.

Double-row ball slewing ring bearing usually comprises 3 rings, steel balls and spacers can enter the upper and lower raceways directly. Two sets of steel ball are placed based on the force analysis. With such configuration, the 90° bearing angles of the upper and lower arc raceway enable the bearing to take large axial force and tilting moment. Special design is needed for the raceway when the radial force is greater than one tenth axial force.

Double-row Ball Slewing Ring with Same Diameter Balls, with Internal Gear

Double-row Ball Slewing Ring with Same Diameter Balls, with External Gear

Double-row Ball Slewing Ring with Same Diameter Balls, with No Gear Structure of double-row ball slewing ring bearing

1 Inner Ring

2 Outer Ring

3 Seal

4 Spacer

5 Ball/Roller Seals

The sealing of the slewing bearing, on the one hand, is to prevent the leakage of filled grease, on the other hand, is to prevent the outside dust, impurities and moisture from invading into the exterior of the bearing and affecting its work. The sealing ring of LYJW slewing bearing is made of nitrile rubber material, which is resistant to high temperature and corrosion.

RacewayThe surface of bearing raceways are quenched, whose quenching hardness is HRC55-62, ensuring its effective hardening depth.

ToothingDue to the need to transmit force, slewing bearings usually have teeth on one of the rings. The toothing is generally normalized or quenched and tempered. Depending on the application, the gears can also be full-tooth hardened or single-tooth inductively hardened. Single tooth inductively hardening can be divided into full tooth hardening and tooth foot (flanks and base) hardening.

Full tooth hardening Tooth flanks and base hardening Tooth flanks Hardening Custom BearingsOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

Tags Slew bearingsdouble-row ball bearings

industrial bearings

turntable rings

manipulator bearings

slew ring bearings wholesale

Links:https://globefindpro.com/products/5436.html

-

Harmonic Drive Bearing

Harmonic Drive Bearing

-

Ball-Roller Combination Slewing Ring

Ball-Roller Combination Slewing Ring

-

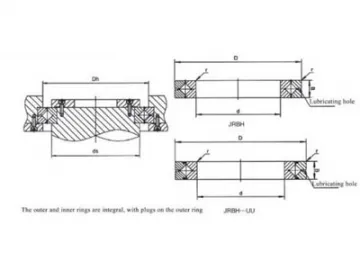

JRBH Series Crossed Roller Bearing

JRBH Series Crossed Roller Bearing

-

JRC Series Crossed Roller Bearing

JRC Series Crossed Roller Bearing

-

MQ1600 Hydraulic Die Cutting Press

MQ1600 Hydraulic Die Cutting Press

-

FSB1600 Full-SERVO Flat & Satchel Paper Bag Machine

FSB1600 Full-SERVO Flat & Satchel Paper Bag Machine

-

JXSU Series Crossed Roller Bearing

JXSU Series Crossed Roller Bearing

-

Single-row Crossed Roller Bearing

Single-row Crossed Roller Bearing

-

Mast Section

Mast Section

-

Electric Scooter for Kids UES100A

Electric Scooter for Kids UES100A

-

Electric Scooter UES200A

Electric Scooter UES200A

-

JRA Series Crossed Roller Bearing

JRA Series Crossed Roller Bearing