Glazing Robot

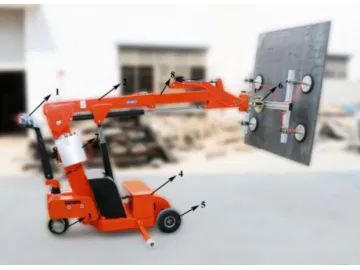

Glazing robots are intelligent manipulators for glazing applications and run on DC power. All functions, including moving, lifting, extension, tilting, side-moving, and vacuum switching are remotely controlled, ensuring multiple applications are achievable, including on-site panel installation, machine feeding, and workshop material handling. All movements are hydraulically achieved, ensuring a continuous, steady operation. A specially designed side moving unit also offers an exceptional fine positioning process during glazing through a side-shift function, assisting a fully loaded machine to easily maneuver through narrow aisles and gates.

Taking a look at the basic WSR400 glass robot as an example, this glass robot was designed specifically for handling dense or semi-porous materials. The robot usually features a tilting function via cylinder or via mechanism unit. Loads must remain within weight limits and load surfaces must be dry, not sharp, and flat, with a pre-set safety vacuum level of 60% (-60kPa).

The glazing robot machine is battery powered, ensuring the machine can carry out glass plate or curtain wall installations both indoors and outdoors with no need for a cable connection. It features a rear wheel driven component to allow the glazing robot to move on its own and offer customers a flexible installation or handling method in all working positions. The machine also contains a hydraulic system, offering excellent performance for lifting, extension, tilting, and side moving. With a reliable mechanical valve, all hydraulic cylinder moving speeds are also stable, making small positioning adjustments during installation easier.

Glazing Robot Parts List:

Driving steering

Boom with telescopic arm

Driving wheel

Battery housing

Front wheel

Rotation/bending unit

Vacuum component housing

Extension arm

We have added an extension robot to increase the mounting height. A variety of options are available to meet specific customer needs:

Links:https://globefindpro.com/products/5445.html

-

Safety Lock for Stop/Fall Arrest

Safety Lock for Stop/Fall Arrest

-

SBH330B/450B-TH Fully Automatic Roll Fed Flat Handle Paper Bag Machine

SBH330B/450B-TH Fully Automatic Roll Fed Flat Handle Paper Bag Machine

-

L Leg Single Person Platform

L Leg Single Person Platform

-

TM-DHL600 Automatic Express Mailer Patching Machine

TM-DHL600 Automatic Express Mailer Patching Machine

-

MQ550 Hydraulic Die Cutting Press

MQ550 Hydraulic Die Cutting Press

-

Material Hoist

Material Hoist

-

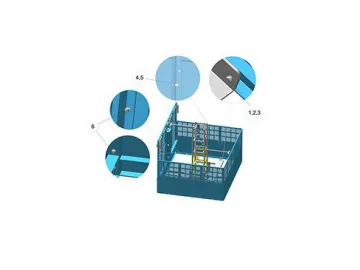

Enclosure

Enclosure

-

Mini Construction Crane

Mini Construction Crane

-

FSB1600 Full-SERVO Flat & Satchel Paper Bag Machine

FSB1600 Full-SERVO Flat & Satchel Paper Bag Machine

-

MQ1600 Hydraulic Die Cutting Press

MQ1600 Hydraulic Die Cutting Press

-

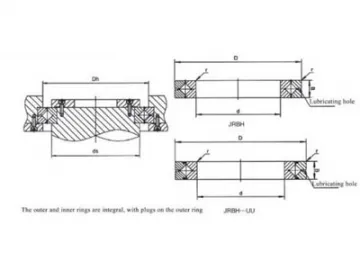

JRC Series Crossed Roller Bearing

JRC Series Crossed Roller Bearing

-

JRBH Series Crossed Roller Bearing

JRBH Series Crossed Roller Bearing