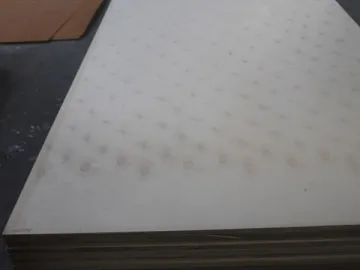

Laminated Veneer Lumber (LVL)

LVL (laminated veneer lumber) is a plywood made through a peeling or chipping process. After drying and gluing the veneers, most, if not all, of the pieces are fit together in a transverse method, then go through a hot press. If all the veneers are placed in a transverse position, the plywood sheet is called an LVL. If they are placed in a longitudinal position, it is called an LVB.

Usage of LVL/LVB:

These plywood panels are divided into 3 primary categories for usage: furniture, construction and packing. The LVL or LVB panel can be used as a door core, a flooring keel or flooring accessories. With its excellent strength, toughness and environmental performance, it has also become a popular choice in crib manufacturing.

In the construction industry, these wood sheets are widely used as engineered wood, scaffolding planks, frameworks and more. LVL is known for its high strength, anti-deformation properties and ease of cutting and nailing. In packing, it is used as a pallet for packing machines, glasses and more. It is low cost, strong, environmentally friendly, and easy to cut.

Construction of LVL

Materials: Poplar/pine

Glue: Melamine, WBP

Popular Sizes:

38x225x3900mm-12000mm

40x235x3900mm-12000mm

42x230x3900mm-12000mm

F & B: Polishing, non-slip, ensuring the safety of construction workers

Edge Processing: Four long edges will be chamfered to convenient and safe holding

Profile: Two sides press mark as per customer's request

Joint Way: Overlap joint, end joint, scarf joint, finger joint

Moisture Content: 8 %~14% at shipment time

Density: 550-700kgs/cbm

Standard: OSHA, ANSI A10.8 (US), BS24829 (UK), AS1577 (AUS), SGS

Advantage: Waterproof, easy to cut, high bending strength

Certificate: ISO901-2000, CE, FSC, SGS

Packaging: Steel strip pallet packing

Min Order: 25cbm/20gp

Trade Terms: FOB, CNF, CIF, EXW

Payment: 30% deposit, 70% balance before shipment with T/T or L/C at sight

Delivery Time: 15~20days after receiving your deposit

Furniture of LVL

Material: Birch, poplar, paulownia, beech wood

Size:

L: 450-----4000MM

W: 35-----1200MM

T: 7-----100MM

Characteristics: Environment protection, no change in shape, high bending strength

Glue: E0, E1, F4

Use & Function: Bed frame slat / queen bed / king bed / school bed (bunk single or double) /outdoor furniture--recliner / beach recliner/ baby bed /children’s bed /electric bed, wooden slats applied to all kinds of bed, sofa and other furniture

Color: Natural, or other paint

Glue: E1, E0

Load Quantity:

20 ~ 22cbm/20'ft

38~50cbm/40'ft

Certificate: ISO9001, ISO14001, CE, SGS, ASTM

Surface: Sanding, decorative paper, veneer

Packing of LVL

Certificate: ISO9001, American CARB

Size: The length is up to 12000mm, the width and the thickness are according to your requirements.

Glue: WBP, MR, E0, E1, E2, Melamine

Material: Poplar, Pine, Birch, Hardwood

Grade: Packing

Joint Way: Overlap joint, end joint, scarf joint, finger joint

Usage: machine packing, pallet packing, glass packing

Features:

1) High bending strength

2) Little linear expansion coefficient

3) Strong nail holding

4) Moisture proof and easy work

5) Tight construction and high strength

6) No rotten wood or decay

7) Low formaldehyde emission

Other search items: LVL Beams and Headers

Links:https://globefindpro.com/products/55407.html