Petroleum Pipeline Steel Pipe

Petroleum Pipeline Steel Pipe

Specifications

| Materials | TP304/304L, TP316/TP316L, TP310S, TP321, TP321H, TP347/TP347H,TP317L etc |

| Standard | ASTM/ASME A312, ASTM/ASME A269 |

| Length | Single Random, Cut Length. |

| Finish | Annealing and pickling, Cold drawing, Cold rolled, Polishing, Mirror, Hairline etc |

| Mainly used for | Fluid transport, including paper mill, sugar mill and nuclear power plant |

| Pipe End | Plain end, beveled end |

| Packing | The Pipe Both End With Plastic Cap, And Then Bundled with Plastic Bags. Or Wooden Cast. |

| Applications | Widely applicable to petrochemical industry equipment, seawater and waste water treatment equipment, oil and gas pipelines. |

| Test | Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection, Nondestructive Test (Ultrasonic flaw detector, Eddy current flaw detector), Hydrostatic Test., |

| Mill Test Certificate | According To EN 10204-3.1. |

Petroleum pipeline steel pipe consists of all sorts ofstainless steel such as TP304 type, TP316L type, TP347H type and so on, which meets theAmerican standard. With high strength and corrosion resistance, this materialcan withstand long term use as well as the pressure resulted from high speed movementof oil.Through annealing, pickling, cold rolled, mirror and other process, our productcan become smooth and glossy without any defects.

This petroleum pipeline steel pipe is mainly applicable to oil transportation.Also, it can be suited for chemical equipment as well as seawater andwastewater devices. Considering the special operating environment, we carry outhydraulic pressure test, mechanical properties and other tests for our productso as to ensure the product quality and the stable operation under theconditions of different temperatures and pressures.

Links:https://globefindpro.com/products/56278.html

-

U Type Solar Collector

U Type Solar Collector

-

Solar Water Heater Repair Parts

Solar Water Heater Repair Parts

-

Modular Inverter System

Modular Inverter System

-

TP600 Industrial Power Inverter

TP600 Industrial Power Inverter

-

Cold Rolled Thin and Narrow Steel Strip

Cold Rolled Thin and Narrow Steel Strip

-

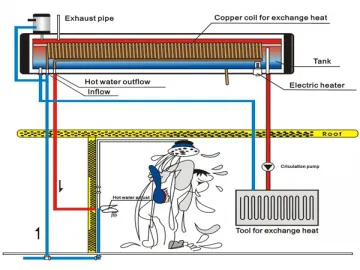

Preheating Solar Water Heating System

Preheating Solar Water Heating System

-

Modular Inverter System

Modular Inverter System

-

TM250A Industrial Modular Inverter

TM250A Industrial Modular Inverter

-

Duplex Stainless Steel Pipe

Duplex Stainless Steel Pipe

-

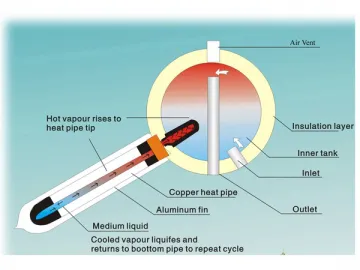

Integrated Pressurized Solar Water Heater

Integrated Pressurized Solar Water Heater

-

Short Radius Steel Pipe Elbow

Short Radius Steel Pipe Elbow

-

Hot Dipped Galvanized Narrow Strip Steel

Hot Dipped Galvanized Narrow Strip Steel