ZC-300H Corrugated Pipe Extrusion Line

ZC-300H is a complete corrugated pipe production line that adopts pressured water cooling method for mould blocks, which helps increase the production speed while lowering power consumption thereby resulting in a better productivity and lower costs for customers. This corrugated pipe extrusion line is quite suitable for manufacturers who produce cable protection conduits, heating system protecting tubes, drainage pipes and stormwater pipes.

Min. pipe ID 50mm

Max. pipe OD 350mm

Total installation power 375kw

Normal working power 230kw

Max. production speed 10.3m/min

Max. output 720kg/hr

Overall dimension(L×W×H) 33m×5.2m×3.3m

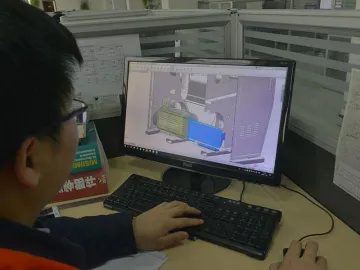

Components of Corrugated Pipe Extrusion Line

Our corrugated pipe extrusion line is mainly composed of extruder, corrugator, cooling bath, cutting machine and unloading device (tilting table).

Single Screw Extruder (Model SJPE-75/33B) 1 set Single Screw Extruder (Model SJPE-90/33C) 1 set Pipe Corrugator (Model ZC-300H) 1 set Spray Cooling Bath (Model 300) 1 set Automatic Sawdust-free Cutting Machine (Model 300) 1 set Unloading Device with Weighing System (Model 300) 1 setLayout of Corrugated Pipe Extrusion Line Features of Extrusion Line Equipment

Single Screw Extruder

Automatic feeding, alarming when lacking of material; The hopper combines functions of drying and storing, automatic temperature control with intelligent display; Extruder screw and barrel are hardened for better wear resistance, increased durability and longer life span; High-efficiency shield-style screw features a special blends melding section, significantly improving the plasticizing efficiency and output; PCC control system, PID temperature control, enabling the temperature to be controlled at the precision of ±1°C; Fully automatic running of the entire extrusion line;Pipe Corrugator, Model ZC-300H

Utilizing water cooled mould blocks, the speed of pipe corrugator is greatly improved; The maximum speed reaches 10.3m/min; High efficiency vacuum system ensures optimal pipe forms; Mould block temperature control system assists in further optimizing the quality of corrugated pipes; Quick and easy mould changeover, efficiently shortening the downtime; Synchronous operation with other equipment such as extruders; Moulds are compatible to ZC-600H and ZC-1000H extrusion lines;Spray Cooling Bath, Model 300

Haul-off unit is fitted at the end of the cooling tank, ensuring the corrugated pipes are stably conveyed into cutting machine; Blow off system is equipped to thoroughly remove the residual water from the surface of corrugated pipes;Automatic Sawdust-free Cutting Machine, Model 300

Swarfless cutting, hydraulically-fed cutting knife ensures precise and burr-free cutting of pipes; Auxiliary inspection mechanism allows the cutting knife to be precisely positioned;Pipe Unloading Device (Tilting Table), Model 300

The height of tilting table is adjustable electrically, providing ease of operation; Equipped with automatic pipe weighing system;Links:https://globefindpro.com/products/5782.html

-

Vibrating Screen Separator

Vibrating Screen Separator

-

Pipe Corrugators

Pipe Corrugators

-

Die Cutting Machine of Printing Machinery, MQ-320

Die Cutting Machine of Printing Machinery, MQ-320

-

ZC-1200H Corrugated Pipe Extrusion Line

ZC-1200H Corrugated Pipe Extrusion Line

-

Capabilities

Capabilities

-

Ecological Concept

Ecological Concept

-

8-Color Intermittent Letterpress High Speed Label Printing Machine, SUPER-320

8-Color Intermittent Letterpress High Speed Label Printing Machine, SUPER-320

-

12 Color Multifunction Flexo Printing Machine, ZTF-330

12 Color Multifunction Flexo Printing Machine, ZTF-330

-

Fully Automatic Label Inspection Machine, ZTJB-320

Fully Automatic Label Inspection Machine, ZTJB-320

-

Purifier

Purifier

-

High Speed Label Slitting and Rewinding Machine, FQ-320/450

High Speed Label Slitting and Rewinding Machine, FQ-320/450

-

Vibrating Air Separator

Vibrating Air Separator