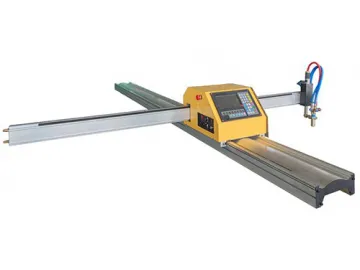

Detachable CNC Plasma Cutting Table, GC-1530

GC-1530 CNC plasma cutting table is a detachable CNC cutting machine combining the features of high speed and high efficiency, suited to cut medium and thin metal sheets & plates that are being mass-produced. The cross beam is characterized by lightweight, small inertia, high precision and ease of installation.

Configured with plasma cutting torch, this CNC cutting table is an efficient energy-saving solution for industrial cutting applications. The detachable design is an important feature which can greatly save shipping cost and container space when shipping via sea.

Comparison Ordinary cutting table occupies 15m3 space, with higher freight costs; Detachable CNC cutting table needs only 7m3 space, with lower freight costs;Cutting mode:

this CNC cutting table is configured with plasma cutting torch, suitable for fast cutting of medium and thin metal sheets & plates. The cutting speed ranges from 50 to 4000mm/min.

| Model | GC-1530 |

| Effective cutting area | 1500×3000mm |

| Cutting speed | 50-4000mm/min (Max. 4000) |

| Power supply | 380V±10%VAC, 50/60HZ three phase 220V±10%V AC, 50/60HZ single phase |

| Plasma cutting | |

| Plasma cutting thickness | 0-15mm Depending on plasma power |

| Torch height control | Arc voltage torch height control |

| Gas types for plasma cutting | N2, O2, compressed air |

| Plasma cutter | 63A-200A |

| Cutting torch | 8m plasma cutting torch |

| CNC control system | F2100T |

| Motor | Stepper motor, servo motor |

| Working precision | ±0.2mm/m |

| Guide rail size (L×W×T) | 2500×2730×1500mm |

| Software | Starcam, Fastcam |

| Cutting mode changeover | Simple changeover between plasma and oxy-fuel cutting. Plasma cutting can be performed by adding plasma power supply, arc voltage torch height control and plasma cutting torch. |

Fangling Cutting Control System (F2100T Built-in Arc Voltage Height Control) The control system adopts 7 inch touch screen, with 49 pre-set patterns which can be easily selected by entering the corresponding number.

Functions

Pattern display 19-language menu Pattern storage, 49 pre-set patterns Metal plate adjustment Automatic kerf compensation Automatically memorize the last cutting point when power off Cutting from current position Offline cutting Online upgradeDouble-axis Linear Guide Rail Adopting high precision linear guide rail, the guiderail in transverse motion is made of lightweight aluminum alloy which features high resistance to deformation, while the longitudinal guide rail offers high precision and stable operation.

Servo Motor, THC and DC Motor These components can work coordinately, providing better performance than that of those parts from different brands.

Limit Switch When cutting torch moves, the limit switch can protect the torch from damaging that is caused by direct impact to the machine.

Software FastCAM Pro is a professional software for plasma and flame cutting machines, it can read or convert various CAD file formats such as DXF, DWG and IGES.

Machine ComponentsPackaging

Tags CNC plasma cutting machinery metal fabrication machines metal cutting systems metal fabricator plasma cutter

Links:https://globefindpro.com/products/5907.html

-

Cooling Unit

Cooling Unit

-

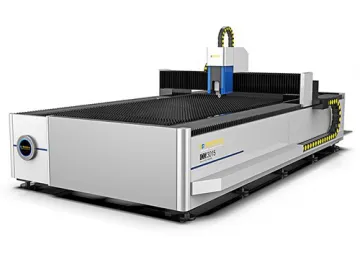

Fiber Laser Cutting Machine, GC-3015

Fiber Laser Cutting Machine, GC-3015

-

Gantry CNC Cutting Machine

Gantry CNC Cutting Machine

-

Environmental Test Chamber (Temperature, Humidity, Altitude and Vibration)

Environmental Test Chamber (Temperature, Humidity, Altitude and Vibration)

-

Air-cooled Vibration Test System

Air-cooled Vibration Test System

-

Mini Gantry CNC Plasma Flame Cutting Machine, GC-3010

Mini Gantry CNC Plasma Flame Cutting Machine, GC-3010

-

Gantry CNC Plasma Flame Cutting Machine, GC-3080

Gantry CNC Plasma Flame Cutting Machine, GC-3080

-

Polyurethane Screens

Polyurethane Screens

-

Portable CNC Flame Cutting Machine, GCF-1530

Portable CNC Flame Cutting Machine, GCF-1530

-

Amber Vibration Controller

Amber Vibration Controller

-

Portable CNC Plasma & Flame Cutting Machine, GC Series

Portable CNC Plasma & Flame Cutting Machine, GC Series

-

HALT & HASS Chamber

HALT & HASS Chamber