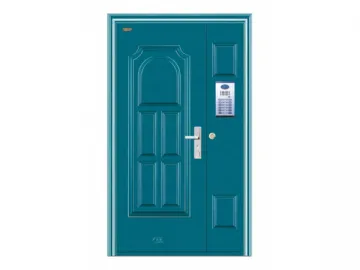

Fog Light Case

Mold

All molds are made from NAK80 steel produced by the Japanese company Daido. Each indicator fully meets mold making requirements of automobile accessory manufacturers.

Material

Depending on the surface and structural characteristics of the product, PP or ABS can be used as the raw materials.

Manufacturing

We use injection molding machines supplied by the Austrian company Engle, to ensure the appearance of the fog light. The joint treatment uses a high-precision vibration friction welding process, so an excellent sealing effect is guaranteed.

Structure

The daytime running light and the fog light casing are designed to match the car’s style. Our designers generally make 3 plans for customers to choose from. Screws can be used for fastening, and the installation is easy. Take the original fog light casing or decorative case off and clamp ours in. The final step is to finish the wiring.

Further Treatment

For processing certain parts for a number of different products that require plating or painting, we have a painting grade of 6 to stay in accordance with the original plating quality with a bump and scratch free surface. Any dirt can easily be cleaned off using a cloth, and we use an imported original lacquer paint to ensure a consistent appearance without shedding and discoloration under normal use.

Links:https://globefindpro.com/products/59421.html