VCS & GHG

To respond to the call of energy conservation and environment protection, SHENGLI has set up effective environment and health safety system, and also adheres to the concept of emission reduction during pipe fittings production. Specifically, we take following measures.

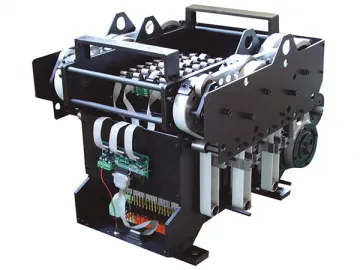

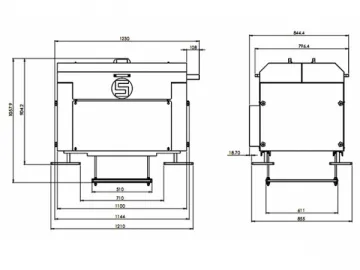

Digital Welding System

Our spiral welded pipe production line is the domestic first line adopting tack welding machine. This machine features high power supplying efficiency and small power consumption, making for notable energy saving effect. Compared with traditional electric welding machine, it saves 30% energy when welding output power is the same.

Welding Flux Recovery System

The welded pipe line adopts advanced welding flux recovery system developed by German Steitz. During production, this system ensures high-efficiency welding flux recovery, reprocessing and reuse, thus maximally reducing environmental pollution.

Plasma Cutting Device

We make use of standalone pipe cutting trolley and special water injection cutting device (ESAB Cutting Systems ESP 400C). During high-speed cutting, the cutting machine uniformly sprays water around plasma electric arc, and thereby cutting quality is guaranteed. Meanwhile, in the process of water gasification, the production of metal melt splashes and particles is avoided. Moisture also restrains waste gas diffusion and thus reduces air pollution.

Pipe Conveying System

All roller tables are made adopting polyurethane silicone. Compared with metal roller tables, they improve welded pipe transportation stability and also prevent resonance and noise caused by impact of pipe and roller table. Thus, noise pollution is eradicated.

Water-Saving Measure

Our hydrostatic testing machine takes full advantages of advanced water circulation system and oil-water separation system. Hence, water consumption is extremely less. Meanwhile, we reuse industrial waste water to save water resource and improve water repeated utilization rate.

Links:https://globefindpro.com/products/60491.html