Welded Stainless Steel Tube

Our welded stainless steel tube comes with two types, 304/L and 316/L. They are available in round tube, square tube, rectangular tube, oval tube, round single slot tube, round double slot tube, square/rectangular single slot tube, square/rectangular double-slot tube, oval single slot tube and so on. Our welding technique is quite excellent, and the surface can be treated with satin polishing technique, and mirror polishing technique. These products can be used as different kinds of decorating stainless steel pipe and pipe product.

Our products are up to related standards both at home and abroad, like GB/T, ASTM, JIS, DIN, and so on. They have used in many industries such as decoration, papermaking, chemical, metallurgy, oil, healthcare, food, furniture, machinery, sewage treatment, and so on. The products have been exported to many countries across the world, and are becoming more and more popular.

Our welding production line is one of the most advanced ones in domestic industry. A group of professional talents are working here. The stainless steel sheet we are using has great quality. So the welded stainless steel tube we provide is also quite durable.

Key production procedures

1. 100% quality stainless steel purchasing

2. Sufficient preparation before production

We have experienced engineers to prepare the machines and moulds, ensuring the precise shape, great welding, and weld bead free surface.

3. Welding quality inspection

We will have a initial inspection on the welded pipes. The qualified tubes will be polished later.

4. Polishing

Polishing is a very important procedure to the product quality. The flaws like scratches, tiny hole, and weld bead trace should be avoided. Before the large scale production, a sample will be provided according to customer's requirements for polishing details. Thus we can make sure that the surface of our welded stainless steel tube will perfectly meet customer's needs.

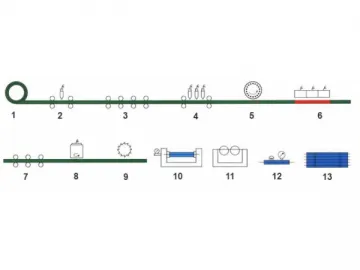

1. Coiling

2. Open volume

3. Forming

4. Welding

5. Inside and outside welded joint processing

6. Luminous solid melt processing

7. Straightening

8. Turbulent flow examination

9. Flies the saw

10. Hydrostatic testing

11. Polishing

12. Examines finally

13. Packing

Links:https://globefindpro.com/products/60787.html