Rockwool (Mineral Wool), Glasswool Sandwich Panel Production Line

Construction

Our rockwool, glasswool sandwich panel production line consists of a large array of advanced equipment, such as the uncoiler with coil feeding car, roll forming machine, caterpillar laminating machine, cut-to-length band saw, the stacker and packing machine, etc.

Besides, microcomputer controlled length and quantity counting device and onsite communication bus are also adopted, thus realizing continuous automated control and production. By virtue of easy operation and reliable performance, this machine is ideal for sandwich panel production.

A. Uncoiling system

B. Roll forming system

C. Preheating room

D. PU glue adhesive system

E. Double belt conveyer

F. Cutting machine

G. Stacking system

H. Packing system

I. Mineral wool cutting&feeding system

J. Mineral wool cutting&feeding system (Trapezoid)

Instruction

Our Advantages

This rockwool (mineral wool), glasswool sandwich panel production line is an upgraded generation machine, improved from original rockwool and EPS sandwich panel production line. It stands out from masses of rivals because of following marvelous advantages:

1. High efficiency

This metal surface mineral wool sandwich panel machine improves production efficiency by 2 times, and crew size is reduced by half. Compared with PRL-6-SA series production line needing 13 operators, this rockwool, glasswool sandwich panel production line only requires 6 operators, thus saving labor cost for manufacturers.

2. High cost performance

This versatile building material manufacturing equipment enables to produce various types of sandwich panels, such as the rock wool type, glass wool type, flat type, hidden type, the corrugated type, etc. Yet, it is sold at an extremely low price. Hence, this is the best chance for you to reduce production cost.

The final products produced by our mineral wool, glasswool sandwich panel production line are widely applied to roof, wall and other fields. The maximum panel thickness can reach up to 300mm, and tailored panel types are available. In short, this line enjoys larger throughput.

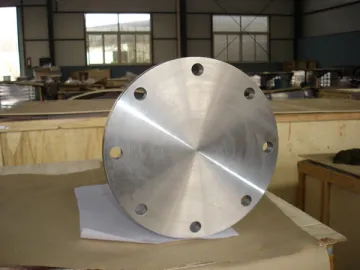

Rock Wool Sandwich Panel Show

1. Rock wool sandwich panel for wall

2. Rock wool sandwich panel for roof

Rockwool SANDWICH

PANEL WALL PANEL 4

Rockwool SANDWICH

PANEL Roof PANEL

Rockwool SANDWICH

PANEL Roof PANEL 2

Components

To make uncoiling speed consistent with roll forming speed, this hydraulic decoiler adopts feedback control system. It is serviceable for steel coil that weighs 6T by means of automatic lifting and tensioning devices.

When the width of steel plate exceeds desired width, edge cutting device is used to cut the superfluous part of steel plate. This device is unpowered, capable of passive cutting under the pulling force of steel plate. Maximum cutting width is 100mm, and produced scraps will be winded by automatic winder.

Top and bottom steel sheets are processed with male and female joint by this machine, making panel installation and splicing more convenient.

90-degree overturning mechanism enables to turn over 2400mm or 1850mm long rock wool strip.

Edge milling mechanism performs edge milling to ensure that rock wool panel meets corresponding requirement.

Its main body is connected by link plate of 1320mm wide, and main body length is 30m. Other lengths are also available. This building material production equipment is capable of top caterpillar band lifting via hydraulic cylinder and guide mechanisms.

As the sandwich panel cutting machine is capable of 180-degree rotation, bothway cutting can be realized.

After cutting, panel clamp and tool rest return to original position, ready for next operation.

Our sandwich panel stacker adopts vacuum lifting system for panel lifting without damage to panel. It enables automatic sandwich panel stacking and comes with dedicated rack for storing unqualified panel scraps. Meanwhile, encoder is used for position detection, making for neat and orderly panel stacking.

User Guide

window.onload =function() {setItemByDivId('container','one|two|three3','etw_link','color:fff; background:#0ca7fa;','color:#fff;background:#1e4ea7','setclass');doget('/loadByJs.php?type=loadByReg&page=/4-8-user-guide/164525&start=start&end=end','setresult')}

Links:https://globefindpro.com/products/61002.html