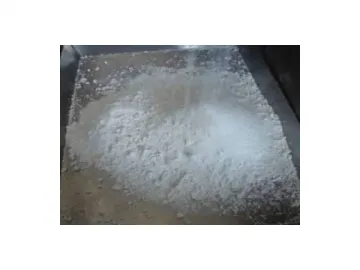

Boric Fertilizer Drying

Drying and Crushing

Boric Fertilizer Drying Equipment

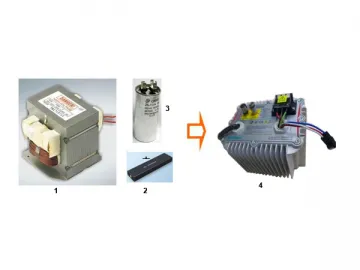

Based on the properties of boric fertilizer, Grandtek specially designed a 50KW boric fertilizer drying equipment for a client in 2007. The materials that needs drying is a high-viscosity fluid materials, so the traditional drying method is ineffective and couldn't ensure uniform drying. Since the utilization of our microwave chemical material dryer, all the aforesaid problems have been settled with effect. The client is capable of efficiently, massively producing boric fertilizer with high drying quality. All in all, our equipment has brought a considerable financial benefit for the client.

Design Features

The 50KW boric fertilizer drying equipment is especially designed according to the actual application.

1. It is configured with a materials feeding mechanism that comes with temperature adjustment function. This function protects boric fertilizer from being affected by temperature variations.

2. Two plates are installed to both sides of the heating cavity, for avoiding the materials dropping during the drying process.

3. Considering the swelling of boric fertilizer while drying, a crushing mechanism is added to the end part of heating chamber. The materials will be crushed prior to discharging.

4. Because the finished boric fertilizer must be powdery, we installed a spiral crushing mechanism to significantly lower the labor intensity and cost for drying. Additionally, the production environment is greatly improved as well.

Links:https://globefindpro.com/products/61233.html