Milling Machine for Pertinax Counter, PERTINAX-1010S

PERTINAX-1010S milling machine is developed especially for production of Pertinax counters, the machining precision can reach ±0.03mm. It is equipped with a 6 tools holder to allow operator to do more complex jobs. Z-axis adopts exclusively designed control unit, automatic aligning system and follow-up processing method, ensuring processing precision. This milling machine can also accomplish rubber cutting, sample making and plotting processes.

Technical Specifications Spindle speed: 1000-60000RPM Spindle power: 1.2kW Cutting speed: 3000mm/min Working area: 1060×1080mm Cutting accuracy: ±0.02mm Spindle tolerance:

Repeat accuracy: ±0.01mm Tool tolerance:

Worktable height: 1.1m Operating mode: Follow-up & CNC Power supply: Three phase 380V±5%\50/60Hz Plotting tool: optional Sample cutting function: optional Features

Self-developed Pertinax counter machine software, can automatically form creasing channels according to the design before cutting;

1.2kW high speed spindle is adopted in quick tool changer, 6 tools holder allows to conduct jobs of creasing, positioning hole drilling, chamfering, cutting and plotting; The software can automatically generate optimal processing path, greatly improving efficiency while guaranteeing processing quality;

Z-axis adopts exclusive design of control mode, automatic aligning and follow-up processing method to provide high processing precision; Computer-controlled depth adjustment gives great operation convenience while ensuring high consistency of creasing depth;

Oscillating knife is optional to cut ejection rubber; High efficiency vacuum cleaner to keep the material surface clean; Interlock protection of machine hardware efficiently prevents spindle from damages caused by signal issues; Tags milling cutter

counter plate milling ejection rubber cutting counter cutter sample maker

Links:https://globefindpro.com/products/6176.html

-

Steel Square

Steel Square

-

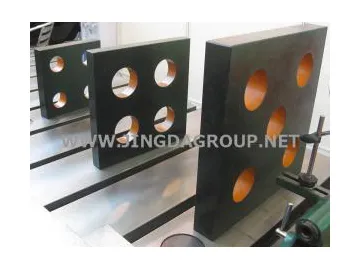

Cast Iron Square Block

Cast Iron Square Block

-

Bridge Building Crane

Bridge Building Crane

-

Granite Parallel

Granite Parallel

-

Container Gantry Crane

Container Gantry Crane

-

Granite Square Ruler

Granite Square Ruler

-

ZC-S500 Implant Dental Chair Package

ZC-S500 Implant Dental Chair Package

-

Bus Paint Booth, GL8 Series

Bus Paint Booth, GL8 Series

-

MTW30,TIG welding Gun

MTW30,TIG welding Gun

-

Roll Forming Machine

Roll Forming Machine

-

BendPro-32B – Automatic Rule Bender for Steel Rule Processing

BendPro-32B – Automatic Rule Bender for Steel Rule Processing

-

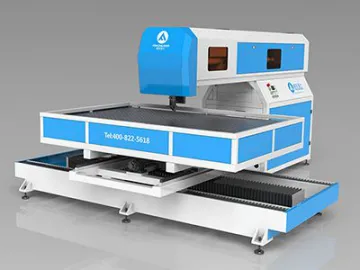

CO2 Laser Cutting Machine (400w/ 600w/ 800w)

CO2 Laser Cutting Machine (400w/ 600w/ 800w)