Flexo Printing Press, MT Series

CI Flexographic Printing Machine for Plastic Film and Nonwoven Printing Substrate material: films(OPP/PET/PE)/ breathable films/nonwovens/paper/cardboards Printing width: 850-1800mm Max. mechanical speed: 300m/min Printing colors: 4/6/8 colors Printing repeat: 400-850mm Max. unwind/rewind diameter: 1100mm Splicing speed: 200m/min  Features Central impression drum is designed with double-wall thermostatic control cooling and circulating system; Machine body is constructed using 120mm ultra-thick panel, ensuring steady printing operation; Independent dryers are installed after each printing unit, offering better drying result; Automated sleeve system for plate cylinder and anilox roll contributes to fast job changeovers; The pressure of plate cylinder and anilox roll is fully controlled by servo motor, offering accurate control and easy operation; Automatic pre-register setting allows for faster machine make-ready with less material waste, efficiently lowering the cost to a minimum; Remote fault diagnosis system assists users in quick troubleshooting; Automatic butt splicer is used for non-stop unwinding and rewinding without slowing or stopping the process, greatly increasing production efficiency and reducing material waste; The corona treatment unit is equipped for better film printing effect; Tags CI flexo presses

Features Central impression drum is designed with double-wall thermostatic control cooling and circulating system; Machine body is constructed using 120mm ultra-thick panel, ensuring steady printing operation; Independent dryers are installed after each printing unit, offering better drying result; Automated sleeve system for plate cylinder and anilox roll contributes to fast job changeovers; The pressure of plate cylinder and anilox roll is fully controlled by servo motor, offering accurate control and easy operation; Automatic pre-register setting allows for faster machine make-ready with less material waste, efficiently lowering the cost to a minimum; Remote fault diagnosis system assists users in quick troubleshooting; Automatic butt splicer is used for non-stop unwinding and rewinding without slowing or stopping the process, greatly increasing production efficiency and reducing material waste; The corona treatment unit is equipped for better film printing effect; Tags CI flexo presses

satellite printing units

web-fed flexo printing press

post-print converting machinery

custom packaging printing

MT series central impression (CI) flexographic printing press is developed on the basis of world's advanced technology in response to the market needs of printing on plastic films, nonwovens and other flexible materials. Utilizing eco-friendly water-based inks aims at reducing pollution. This flexo printing press is featured by full servo control, ease of use and low production cost. As per customer’s request, this series flexo printing machine is configurable with in-line post-print converting functions for user’s individual production demands.

satellite printing units

web-fed flexo printing press

post-print converting machinery

custom packaging printing

Scan QR to Read

Links:https://globefindpro.com/products/6239.html

Links:https://globefindpro.com/products/6239.html

Recommended Products

-

Flexo Printing Press

Flexo Printing Press

-

5-8kW Induction Heating Power Supply (Wall Mounted)

5-8kW Induction Heating Power Supply (Wall Mounted)

-

20-30kW Induction Heating Power Supply (Floor Standing)

20-30kW Induction Heating Power Supply (Floor Standing)

-

2-5kW Induction Heating Power Supply (Wall Mounted)

2-5kW Induction Heating Power Supply (Wall Mounted)

-

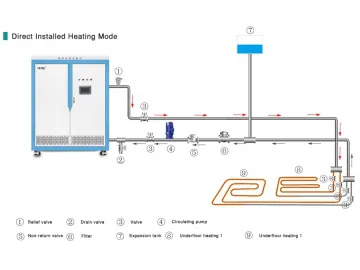

Commercial Induction Central Heating Boiler

Commercial Induction Central Heating Boiler

-

Shaped Pouch

Shaped Pouch

-

Flexo Printing Press, TH Series

Flexo Printing Press, TH Series

-

Double Girder Gantry Crane

Double Girder Gantry Crane

-

Material Handling Crane

Material Handling Crane

-

Flexo Plate Mounting Machine

Flexo Plate Mounting Machine

-

Flexo Printing Press, SC Series

Flexo Printing Press, SC Series

-

Single Beam Gantry Crane, with L-shaped Legs

Single Beam Gantry Crane, with L-shaped Legs