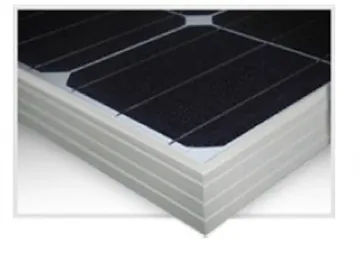

30P 230W/235W/240W/245W/250W Poly Solar Panel

30P 230W/235W/240W/245W/250W Poly Solar Panel

Benefits

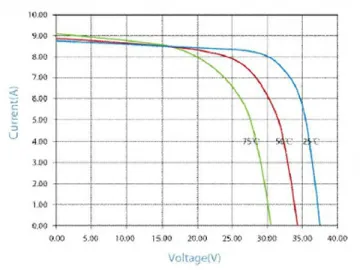

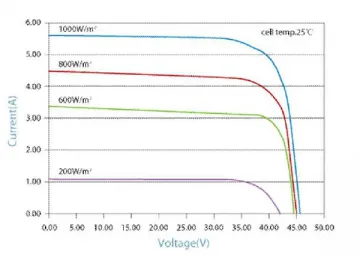

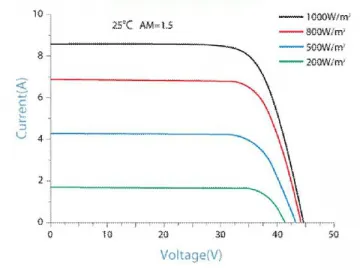

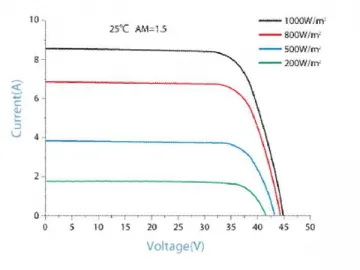

I-V Curves

Engineering Drawings

SL230-250TU-30P

Electrical Data

Maximum Power (W) | 230 | 235 | 240 | 245 | 250 |

Optimum Power Voltage (Vmp) (V) | 30.36 | 30.60 | 30.72 | 30.85 | 31.02 |

Optimum Operating Current (Imp) (A) | 7.58 | 7.68 | 7.81 | 7.94 | 8.06 |

Open Circuit Voltage (Voc) (V) | 36.42 | 36.54 | 36.60 | 36.91 | 36.99 |

Short Circuit Current (Isc) (A) | 8.1 1 | 8.22 | 8.36 | 8.50 | 8.62 |

Photoelectric Conversion Efficiency of Solar Cell (%) | 16.07 | 16.42 | 16.77 | 17.11 | 17.46 |

Photoelectric Conversion Efficiency of Whole Module (%) | 14.17 | 14.47 | 14.78 | 15.09 | 15.40 |

Wattage Tolerance | 0% to 3% | ||||

Nominal Operating Cell Temperature (°C) | 47±2 | ||||

Temperature Characteristics

Temperature Coefficient of Isc (%) | 0.04 |

Temperature Coefficient of Voc (%) | -0.35 |

Temperature Coefficient of Pm (%) | -0.45 |

Temperature Coefficient of Im (%) | 0.04 |

Temperature Coefficient of Vm (%) | -0.35 |

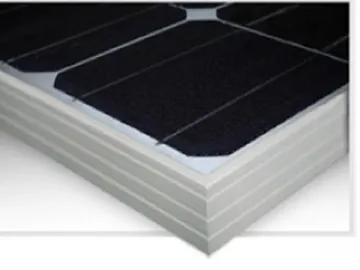

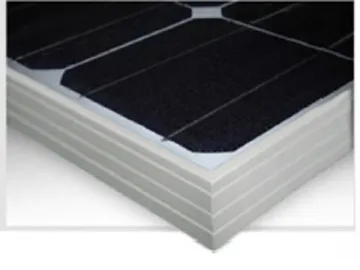

Components and Technical Data

Solar Cell (mm) | 156×156 Poly Type |

Number of Cell (pcs) | 6×10 |

Size of Module (mm) | 1640×990×40 |

Front Glass Thickness (mm) | 3.2 |

Maximum Load Capacity of Surface (Pa) | 2400-5400 |

Allowable Hail Load | 23m/s, 7.53g |

Weight Per Piece (kg) | 18.6 |

Junction Box Type | TUV Certification |

Bypass Diode Rating (A) | 12 |

Cable and Connector Type | TUV Certification |

Frame | 46mm Aluminum Alloy |

Back Sheet | TPT |

Temperature Range (°C) | -40 to 85 |

Fill Factor (%) | 70-76 |

Standard Test Conditions | AM 1.5, 1000W, 25±2°C |

Packing

Packing | Wooden Box |

1×20 inches Container | 14Pallets/332pcs |

1×40 inches HQ | 28Pallets/840pcs |

The SL230-250TU-30P series of poly solar panels has high performance with the maximum power of 230W, 235W, 240W, 245W and 250W. They are designed with the dimension of 1640×990×40mm, weight of 18.6kg and operating temperature ranging from -40°C to 85°C.

By using the solar cell with high energy conversion efficiency, the poly solar panel has the features of high energy utilization rate, energy saving and environmental protection. Its back sheet is made of TPT material which is high flame retardant. Through lamination and good encapsulation, the product has firm structure and good sealing performance. Featuring favorable weathering resistance and excellent capabilities of resistance to wind, hail, humidity and salt spray corrosion, it won’t be influenced by the geographical environment and can be used for commercial solar power generation system. Welcome customers to purchase our product.

Links:https://globefindpro.com/products/63149.html

-

48V 250W/255W/260W/265W/270W White Mono Solar Panel

48V 250W/255W/260W/265W/270W White Mono Solar Panel

-

Black White High Gloss Metallic PVC Film

Black White High Gloss Metallic PVC Film

-

Purple High Gloss Metallic PVC Film

Purple High Gloss Metallic PVC Film

-

36V 190W/195W/200W /205W/210W White Mono Solar Panel

36V 190W/195W/200W /205W/210W White Mono Solar Panel

-

30V 240W/245W/250W/255W/260W Monocrystalline White Solar Panel

30V 240W/245W/250W/255W/260W Monocrystalline White Solar Panel

-

Water Pink High Gloss Printing PVC Film

Water Pink High Gloss Printing PVC Film

-

Red High Gloss Printing Plastic Film

Red High Gloss Printing Plastic Film

-

Blue High Gloss Printing PVC Film

Blue High Gloss Printing PVC Film

-

36P 265W/270W/275W Poly Solar Panel

36P 265W/270W/275W Poly Solar Panel

-

Yellow Flower Printing High Gloss Film

Yellow Flower Printing High Gloss Film

-

36V 175W/180W/185W White Mono Solar Panel

36V 175W/180W/185W White Mono Solar Panel

-

36V 290W/295W/300W/305W/310W TU Certified White Mono Solar Panel

36V 290W/295W/300W/305W/310W TU Certified White Mono Solar Panel