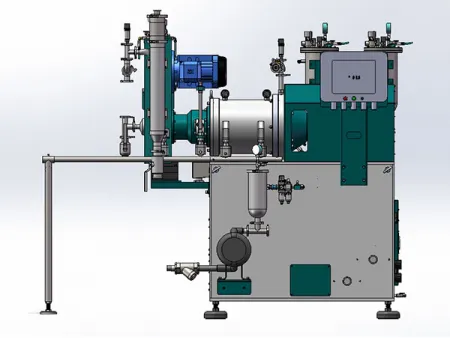

Horizontal Pin Bead Mill, RTSM-1000BJP

This horizontal pin bead mill can deliver micron-level and nano-level final fineness, which means this grinding machine is applicable for medium-to-low viscosity and smooth fluid materials. This bead mill features reasonably-designed rotor, which involves simulated and actual operation. This is why this horizontal grinding machine can operation with marvellous grinding efficiency, average-temperature operation and low energy cost. Given that, this pin bead mill is widely used in industries such as pigments, pesticides, fertilizers and ink.

Model No. RTSM-1000BJP

Volume: 1000L

Power: 500kW

Materials of Inner Grinding Chamber Component: Silicone Carbide

Materials of Outer Grinding Chamber Component: SS304 Stainless Steel

Grinding Principle: Pin Type

Materials of Rotor Component: SS304 Stainless Steel and PU (Polyurethane)

Max. Line Speed: 15m per second

Materials of Screen Component: SS304 Stainless Steel

Operation Method: PLC with Touch Screen

Mechanical Seal: Double-end Container Type

Pneumatic Diaphragm Pump: 3-inch Pneumatic Diaphragm Pump

Scan QR to Read

Links:https://globefindpro.com/products/699.html

Links:https://globefindpro.com/products/699.html

Recommended Products

-

Automatic Strapping Machines

Automatic Strapping Machines

-

Horizontal Double-Drive Nano Bead Mill, RTSM-10BJD-S

Horizontal Double-Drive Nano Bead Mill, RTSM-10BJD-S

-

Atmospheric Pressure Fully Sealed Air Insulated RMU (up to 12kV)

Atmospheric Pressure Fully Sealed Air Insulated RMU (up to 12kV)

-

95% Zirconia Beads

95% Zirconia Beads

-

Battery Powered Strapping Tools

Battery Powered Strapping Tools

-

Articulated Arm Suction Cup Tablet Mount, VMA-P1/P1B

Articulated Arm Suction Cup Tablet Mount, VMA-P1/P1B

-

Extension Rod, LPT-2872-001

Extension Rod, LPT-2872-001

-

Manual Combination Strapping Tools

Manual Combination Strapping Tools

-

Horizontal Pin Bead Mill, RTSM-400BJP

Horizontal Pin Bead Mill, RTSM-400BJP

-

Stretch Wrapping Machines

Stretch Wrapping Machines

-

Bluetooth Remote, LY

Bluetooth Remote, LY

-

PP Strapping

PP Strapping