Freight Elevator

Customer Selection

1. The cargo elevator is available in machine room type, no machine room type, and hydraulic.

2. The maximum working load is 16 t for the traction type, 7t for no machine room, and 50t for hydraulic.

3. According to actual conditions, the cargo elevator is designed with 2S, 2CO, 3S, 3CO, 2U, 3U, and other door opening methods to achieve a maximum width for easy entry and exiting with large cargo.

4. Car Components Selection

Ceiling: Stainless steel plate with hairline treatment and baked enamel (color is optional), Flat hung ceiling, Acrylic lighting decoration

Ventilation: Axial fan

Car wall: Stainless steel plate with hairline treatment and baked enamel (color is optional)

Floor: Riffled steel plate

Features of the Cargo Elevator

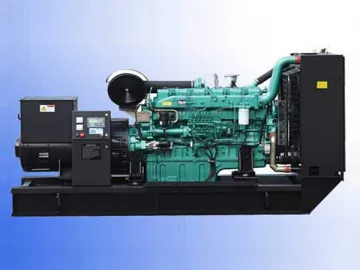

1. Stable Running, High Comfort

This service elevator uses a variable frequency motor that allows the lift to run smoothly and in a stable manner, thus ensuring the comfort of the ride. It is also designed with a device that weighs the load in the car before it starts, to ensure a stable operation.

2. Excellent Protection System

Our cargo elevator is designed with an excellent protection system, which covers protection against hoist rope slipping, urgent inching and starting protection, motor overheating protection, up-traveling over speed protection, sinking protection and more. Due to the protection system, the vertical conveyor can slow or stop when it encounters an emergency and thus ensure the cargo's integrity and safety.

3. Robust, Longer Service Life

Made using high intensity plate bending and forming technology, the lift car is sturdy and durable. It is also available with specially designed anti-collision guardrails, so the car is equipped with multi-protection aspects.

4.Easy Operation, User-friendly Special Functions

1) Automatic fault recording: the controller for the cargo elevator can record and display the latest faults so that they can be removed quickly and the lift can recover.

2) Fire emergency return: When a fire emergency occurs, the key switch in the base station or on the monitoring screen will be unlocked, and all instructions to the lift will be cancelled, allowing the lift to immediately land on the rescuing floor and open the door automatically.

3) Intelligent weighing device: the goods lift is designed with a high precision dish load sensor to detect the electric signal caused by local change in the car, and utilizes a single chip microcomputer to conduct scientific operations to the signal, achieving an effective load weighing.

4) Door close delay function: Pressing the door close delay button on the inside or outside of the COP allows the door to remain open for 3 minutes or longer according to customer needs. When the delay ends, press the door close button, and the door will close. This is great for loading and unloading cargo.

Specifications of the Cargo Elevator

| Product name | Type | Loading capacity | Rated speed | Car size | Access | Shaft | Machine room | |||||||

| Cargo Elevator | Sorts | Traction | kg | m/min | mm | mm | mm | mm | ||||||

| AA | BB | H | JJ | X | Y | PIT | O.H | |||||||

| Machine room | F-1000-2S | 1000 | 20 30 45 | 1500 | 1600 | 2300 | 1100 | 2350 | 2100 | 1500 | 4500 | 3000 | 3300 | |

| F-2000-2CO | 2000 | 2000 | 2100 | 1600 | 3000 | 2700 | 3600 | 3900 | ||||||

| F-3000-2S | 3000 | 2300 | 2500 | 2500 | 1800 | 3300 | 3100 | 1800 | 4800 | 3900 | 4300- | |||

| F-4000-2CO | 4000 | 2400 | 3000 | 2000 | 4000 | 3700 | 4600 | 4900 | ||||||

| F-5000-2CO | 5000 | 3000 | 3000 | 2500 | 4200 | 3700 | 5200 | 5000 | ||||||

| Machine room free | F-1500-2S | 1500 | 30 | 1700 | 2000 | - | 1400 | 2700 | 2800 | 1600 | - | - | - | |

| F-2000-2S | 2000 | 1900 | 2200 | 1600 | 3000 | 3000 | 1700 | |||||||

| F-3000-2S | 3000 | 2300 | 2500 | 1900 | 3400 | 3500 | 1800 | |||||||

Notes:

1. The technical data shown above is acquired from sample test. It is only for reference. Due to different test methods and environmental deviation, actual data varies slightly;

2. Yuancheng can carry out production according to the standards agreed by both sides.

Links:https://globefindpro.com/products/69972.html