Butterfly Cone Fan

Coming with a horn-shaped air outlet, our butterfly cone fan features a high air draft capacity, as well as a stable air exhaust volume. It uses a front-mounted double-door opening mechanism and rubber sealing device, making this butterfly fan have a great sealing performance, low air resistance, and a high working efficiency.

If you have multiple fans in your factory, you can start them at asynchronously in accordance to your needs, avoiding backflow of air, and improving operating efficiency. This butterfly cone has a working efficiency that is 15 to 20% higher than other exhaust fans with equal power.

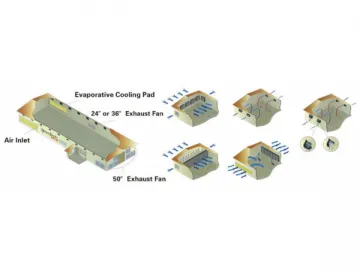

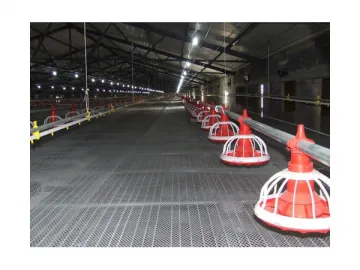

Application

The butterfly cone fan we produce is suitable for a wide range of applications, and different industries, including agriculture, flowers and plants, stock farming, mining, chemical, medical, grain, tea and wood.

Working Capacity

Using this ventilation fan, 700m3 of indoor air can be exchanged with the outdoor air nearly 73 times within an hour. Employed with our design scheme, the indoor air speed of your workshop is roughly 3.5 m/s.

Structural Features

Designed in a reasonable horn shape, the air outlet allows for a large air flow, a high air draft capacity, and stable air exhaust volume for our butterfly cone fans.

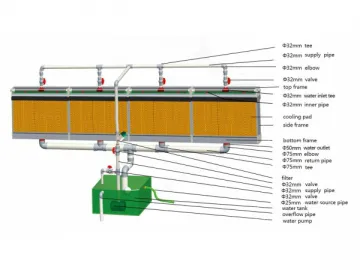

Made of an aluminum alloy, the shutter in our ventilation fan is of light weight and makes your room more visually appealing. There is an auxiliary open mechanism that guarantees the shutter can be opened smoothly at the proper angle with less air resistance.

The blades in our butterfly cone fan are produced by press forming Crupp self-cleaning stainless steel material. This steel is 1.2mm thick and the surface finish is BA. The fan blades are visually appealing and do not deform easily or get dusty.

Belt pulleys we use are made from high strength and light weight anti-corrosive aluminum magnesium alloy, which reduces the overall weight of the fan blades. Designed with three reinforced ribs, and treated with sand blasting and internal stress relievers, the belt pulleys also looks beautiful and are difficult to break.

Bearings of this exhaust fan are double row bearings imported from France. These carry several advantages, including a waterproof performance, low noise emission, high strength, long service life and little to no maintenance.

Fan blades used in our products are calibrated with an advanced computer-controlled dynamic balance tester to ensure the stability, lower the noise, and extend the service life of our ventilation equipment.

Hot dipped galvanized pillars and protection wire nets that never get rusty are used in our butterfly cone fan.

CNC streamlined production makes the ventilators visually appealing and ensures stable quality.

Technical Details

| Model | QCHS-1000 | QCHS-1250 | QCHS-1300 |

| Blade diameter (mm) | 1000 | 1250 | 1300 |

| Blade rotational speed (rpm) | 600 | 439 | 439 |

| Motor rotational speed (rpm) | 1400 | 1400 | 1400 |

| Air flow (m3/h) | 28000 | 43000 | 46000 |

| Total pressure (Pa) | 70 | 80 | 80 |

| Noise (dB) | ≤65 | ≤65 | ≤65 |

| Input power (W) | 750 | 1100 | 1100 |

| Rated voltage (V) | 380 | 380 | 380 |

| Height (mm) | 1100 | 1380 | 1380 |

| Width (mm) | 1100 | 1380 | 1380 |

| Thickness (mm) | 1150 | 1300 | 1300 |

Air Flow Curve Chart Installation Cases

Links:https://globefindpro.com/products/71830.html