Hydraulic Press

This hydraulic press machine could be used for metal processing such as stretching, bending, flanging, cold extrusion, punching. It is also for press forming of power products, abrasive products, plastic products and insulation products.

Features of Hydraulic Press

This four column hydraulic press has optimized design, laconic structure and high working efficiency. The hydraulic control system of this hydraulic pressing machine adopts cartridge valve manifolds, credited for reliable performance, long service life and small hydraulic impact. Moreover, this control system reduces the usage of connection pipe and leakage points.

The independent electrical control system, reliable in operation and convenient in maintenance, employs the button-control or semi-automatic control. Based on its scientific design, this pressing equipment could process materials at a constant pressure or constant distance. Additionally, it enjoys an advantageous function of time delay of press forming under fixed pressure. The working pressure and stroke could be adjusted within the defined limits.

This hydraulic press machine could be used for the stretching, bending, flanging, cold extrusion, punching, press fitting correction of metal materials and production of power products, abrasive products, plastic products and insulation products.

Hydraulic Press Optional Accessories

To ensure the smooth operation of the machine press we provide, we now provide the following optional accessories to customers

1.Blanking buffer device;

2. movable worktable;

3. screen protection device;

4. oil cooling device;

5. touch screen;

6. feeding device(hydraulic or mechanical);

7. quick-acting die clamping system;

8. imported PLC system;

9. floating guide-way and rolling bracket designed for die change;

10. top-mounted hydraulic system;

11.slide stroke locking device.

| Series number | Item | Unit | YD32-40 | YD32-63 | YD32-100 | YD32-160 | YD32-200 | YD32-315 | YD32-400 | YD32-500 | YD32-630 | YD32-800 | YD32-1000 | YD32-1250 | |

| 1 | Nominal capacity | kN | 400 | 630 | 1000 | 1600 | 2000 | 3150 | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | |

| 2 | Return stoke force | kN | 150 | 250 | 320 | 320 | 500 | 600 | 840 | 1000 | 1250 | 1660 | 2050 | 2500 | |

| 3 | Ejection return force | kN | 120 | 190 | 190 | 400 | 630 | 630 | 630 | 1000 | 1000 | 1600 | 2000 | 2000 | |

| 4 | Max working pressure for the liquid | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| 5 | Slide stroke | mm | 400 | 400 | 600 | 700 | 700 | 800 | 800 | 900 | 900 | 900 | 900 | 900 | |

| 6 | Ejection stroke | mm | 150 | 200 | 200 | 200 | 300 | 300 | 300 | 350 | 350 | 450 | 450 | 450 | |

| 7 | Max opening height | mm | 600 | 700 | 900 | 1000 | 1100 | 1250 | 1300 | 1500 | 1700 | 1800 | 1800 | 1800 | |

| 8 | Slide stroke speed | Descending with no load | mm/s | 80 | 100 | 120 | 100 | 120 | 100 | 100 | 100 | 100 | 120 | 120 | 120 |

| Working | mm/s | 10 | 10 | 14 | 12 | 12 | 10 | 10 | 10 | 10 | 8 | 8 | 8 | ||

| Return stroke | mm/s | 52 | 50 | 47 | 80 | 80 | 60 | 60 | 80 | 80 | 50 | 50 | 50 | ||

| 9 | Effective size of worktable | Left-right | mm | 500 | 570 | 720 | 1000 | 1000 | 1260 | 1260 | 1400 | 1500 | 1800 | 2000 | 2000 |

| Front-rear | mm | 460 | 500 | 560 | 800 | 900 | 1100 | 1200 | 1400 | 1500 | 1600 | 1800 | 1800 | ||

| 10 | Boundary dimension | Left-right | mm | 1400 | 2000 | 2160 | 2500 | 2600 | 3260 | 3260 | 4800 | 4800 | 4800 | 5200 | 5200 |

| Front-rear | mm | 1200 | 1380 | 1600 | 2000 | 2500 | 2580 | 2580 | 2800 | 3000 | 4000 | 4300 | 4300 | ||

| Height(above ground) | mm | 2600 | 2760 | 3160 | 3400 | 3800 | 4300 | 4500 | 5200 | 5620 | 6000 | 6450 | 6450 | ||

| 11 | Motor power | kW | 4 | 7.5 | 7.5 | 11 | 15 | 15 | 22 | 37 | 37 | 45 | 75 | 75 | |

Links:https://globefindpro.com/products/72035.html

-

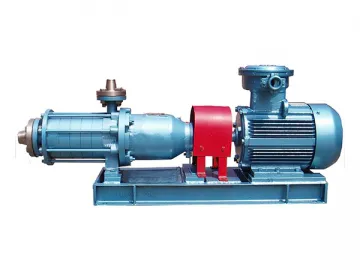

MCM Magnetic Drive Pump (Low Flow High Head Pump)

MCM Magnetic Drive Pump (Low Flow High Head Pump)

-

Roof Tile (Lightweight Roofing)

Roof Tile (Lightweight Roofing)

-

UPVC Roofing Sheet (940 mm Plastic Roofing Sheet)

UPVC Roofing Sheet (940 mm Plastic Roofing Sheet)

-

CNC Hydraulic Swing Beam Shear

CNC Hydraulic Swing Beam Shear

-

Synthetic Roof Tile

Synthetic Roof Tile

-

Plastic Roofing Sheet (PVC Corrugated Sheet)

Plastic Roofing Sheet (PVC Corrugated Sheet)

-

CNC Hydraulic Guillotine Shear

CNC Hydraulic Guillotine Shear

-

FRP Roofing Sheet

FRP Roofing Sheet

-

PZ973 Electric Knife Gate Valve

PZ973 Electric Knife Gate Valve

-

DMZ673 Pneumatic Knife Gate Valve

DMZ673 Pneumatic Knife Gate Valve

-

PZ973 Electric Knife Gate Valve(Double Clip Type)

PZ973 Electric Knife Gate Valve(Double Clip Type)

-

PZ643 Pneumatic Knife Gate Valve (Double Clip Type)

PZ643 Pneumatic Knife Gate Valve (Double Clip Type)