200T Hot Press (Pressing Machine for Wood Door and Panel )

JINLUN's 200T hot press is designed for use in wooden door factories, furniture factories, and artificial board secondary processing factories for hot pressing such items as building partitions, wooden panels, and wooden doors. The entire pressing process only takes 13 seconds, easily keeping up with the speed of your daily output.

As an innovative woodworking equipment manufacturer, JINLUN is continually upgrading the designs and features of our machines. The hot press is no exception as we now offer a range of designs to best fit your processing needs.

Structural Features of the 200T Hot Press

1. Heating Platen

The heating platen is made from a carbon steel plate with drilled holes for strength and durability. A working table of 2700mm×1370mm allows users to easily operate the wood working machine.

2. Heating System

The hot press comes with a special heating system which employs a heat transference oil boiler that features a countercurrent flow and a high temperature, and lowers the system pressure to meet safety requirements. The heat system's closed circulation transfers energy via liquid, thus reducing heat loss and saving overall energy.

3. Hydraulic System

This type of hot press is a hydraulic plywood press with adjustable hydraulic pressure.

4. Oil Cylinder

The oil cylinder is made with high precision tools, and sealants prevent oil from leaking.

5. Control System

Our hot press is equipped with a microcomputer control system for both manual and automatic control. With a simple push of a button you can control a whole set of processes including pressing plate ascending, closing, pressure adding, pressure maintaining, timing and pressing plate descending.

Technical Parameters of 200T Hot Press

| Model | BY21-4×8/20-3 |

| Number of oil cylinder | 6 |

| Oil cylinder diameter | Φ140mm |

| Oil cylinder stroke | 700mm |

| No-load closing time | About 13s |

| Hydraulic system | Manual and automatic control (International warranty service) |

| Proof pressure | 25Mpa |

| Main motor power | 7.5kW |

| Pressing motor power | 5.5kW |

| Main oil pump | 100:100 Double vane pump |

| Pressing oil pump | 10ml/rev (plunger pump) |

| Perforated plate size | 2500 ×1300 ×42mm (CE Authentication) |

| Interlayer spacing | 130mm |

| Mainframe steel plate thickness | 30mm, 22mm, 12mm |

| Upper, lower and moved cross beam height | 450mm, 450mm and 300mm |

| Moved cross beam size | 2500×1300×300mm |

| Main frame size | 2960×1300×2500mm |

Links:https://globefindpro.com/products/73216.html

-

T/C Fabric Apron (Apron made with Polyester Cotton Fabric )

T/C Fabric Apron (Apron made with Polyester Cotton Fabric )

-

Terry Pot Holder (Custom Shape Potholder with Terry Cloth Fabric)

Terry Pot Holder (Custom Shape Potholder with Terry Cloth Fabric)

-

Custom Printed Pot Holder

Custom Printed Pot Holder

-

Insulated Bag (Custom Bag as Pizza Delivery Bag)

Insulated Bag (Custom Bag as Pizza Delivery Bag)

-

Terry Oven Mitt

Terry Oven Mitt

-

Large Water Tank Steam Mop

Large Water Tank Steam Mop

-

Non-Woven Bag (Eco-friendly Bag with Custom Shapes)

Non-Woven Bag (Eco-friendly Bag with Custom Shapes)

-

Oven Mitt ( Mitts with Silver Coated Surface )

Oven Mitt ( Mitts with Silver Coated Surface )

-

PVC Bag (Custom Plastic Bag as Packaging and Shopping Bag)

PVC Bag (Custom Plastic Bag as Packaging and Shopping Bag)

-

Synthetic Fiber Bag (Bags with Custom Printed Pattern)

Synthetic Fiber Bag (Bags with Custom Printed Pattern)

-

VRV Air Conditioning Unit

VRV Air Conditioning Unit

-

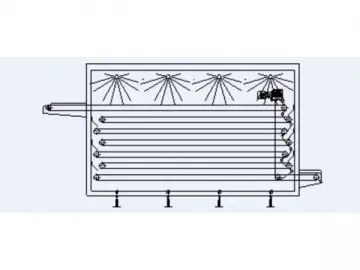

Multipass Tunnel Freezer

Multipass Tunnel Freezer