Y11 Series Circular Connectors

Thanks to the bayonet coupling mechanism, connecting and disconnecting the Y11 series circular connector is easy. Lightweight, compact design allows the female connector to take up little space when mounted onto the bulkhead, panel or box. Solder contact accepts the wire which is soldered onto the solder cup.

Different seal styles exist for the male connector, such as general seal, compression seal, and airtight seal. The shell of the connector can come with shielding features to prevent electromagnetic interference during signal transmission. It also offers protection against salt-spray, rain, and sands. Built in compliance with GJB101A-97 requirements, the Y11 series circular connector can be used to replace YL1 series electrical connector.

There are mainly two types of seal for the receptacle connector, including potting and glass sealing. The female connector can be mounted onto an enclosure via flange, coupling nut or through-the-wall mount.

If you are from one of the following industries and you are currently looking for a rugged connector pair, please do consider KAIDA connector as an option.

1. Tactical weapon system

2. Aerospace satellite

3. Air or sea transportations

4. Ground transmitter, ground receiver

5. Industrial system with high heat, high energy demand

6. Communications system, testing system

7. AC industrial power supply system

Technical Specifications of Y11 Series Circular Connector

Environmental Performance

| Working Temperature | -55°C ~ 125°C (solder contact) |

| Relative Humidity | 95% (40°C) |

| Operating Height | Altitude: 30000m |

| Vibration | Frequency: 10Hz~2000Hz Acceleration: 196m /s² |

| Shock | Acceleration: 490 m /s² |

| Air Tightness | Allowable Pressure: 0.2Mpa (Type of seal: potting compound) |

Electrical Performance of Y11 Series Circular Connector

Contact Resistance, Rated Current

| Contact Specifications (mm) | Contact Resistance (mΩ) | Rated Current (A) |

| Φ1.0 | ≤5 | 5 |

| Φ1.5 | ≤3 | 10 |

Electrical Continuity (between the braided metal sheath and the connector shell without shielding feature): ≤200mΩ

Electrical Continuity (between the braided metal sheath and the connector shell with shielding): ≤5 mΩ

Minimum Attenuation: 45dB (with radio frequency interference at a frequency up to 8000MHz)

Rated Voltage, Withstand Voltage and Insulation Resistance

| Working Environment | Rated Voltage (V) | Withstand Voltage (V) | Insulation Resistance (mΩ) |

| Ambient Temperature and Pressure | 500 | 1500 | ≥30000 |

| Damp-Heat | 500 | 500 | ≥20 |

| High Temperature | 250 | ---- | ≥500 |

| Low Pressure (1kpa) | 150 | 200 | ---- |

Mechanical Performance of Y11 Series Circular Connector

| Shell | High-strength aluminum alloy, copper alloy |

| Coating (without shielding) | Integral Color Anodizing |

| Coating (with shielding) | Nickel electroplating |

| Dielectric | Heat-resistant thermoplastic |

| Grommet and Seal Ring | Silicone rubber |

| Contacts | Copper alloy |

| Plating | Gold |

| Service Life | 500 mating cycles |

Download Datasheet

Links:https://globefindpro.com/products/73905.html

-

6-Way Surge Protector Power Board

6-Way Surge Protector Power Board

-

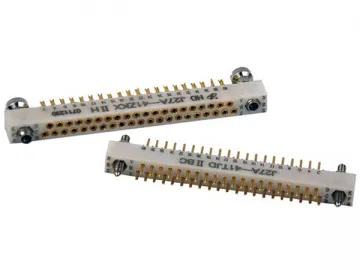

MIL-DTL-55302 Connectors

MIL-DTL-55302 Connectors

-

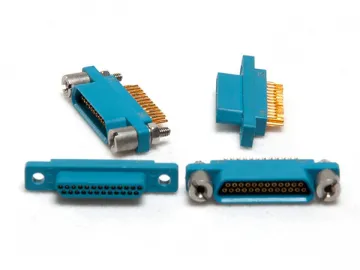

MIL-DTL-38999 Connectors

MIL-DTL-38999 Connectors

-

Wire Harness for Micro-D Connectors

Wire Harness for Micro-D Connectors

-

J29 Series Rectangular Connectors

J29 Series Rectangular Connectors

-

Y2 Series Circular Connectors

Y2 Series Circular Connectors

-

8-Way German/French Type Socket

8-Way German/French Type Socket

-

8 Way Master Slave Power Board

8 Way Master Slave Power Board

-

6 Way Surge Protected Power Board

6 Way Surge Protected Power Board

-

J27A Series Rectangular Connectors

J27A Series Rectangular Connectors

-

2 Way Surge Protector Power Board with 2.1A USB Charger

2 Way Surge Protector Power Board with 2.1A USB Charger

-

J30 Series Rectangular Connectors

J30 Series Rectangular Connectors