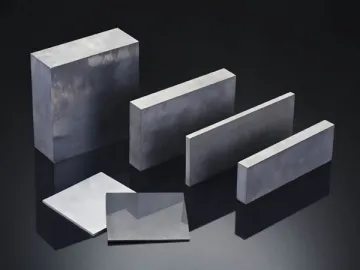

Tungsten Carbide Blanks (For Powder Metallurgy Dies)

This range of tungsten carbide blanks are used for making powder metallurgy dies and die components. All of our carbide blanks have undergone the HIP process, and we can assure you that the resulted tungsten carbide dies have no holes or blisters. The powder metallurgy dies produced using our tungsten carbide preforms also feature good wear resistance and superior polishing performance.

As one of our superior carbide products, this selection of tungsten carbide blanks can be applied to the powder metallurgy dies manufacturing with iron base, copper base, ceramics and cemented carbide. The customization of the carbide blank shape is available.

Recommended Designations of Tungsten Carbide Blanks for Powder Metallurgy Dies| Designations | JZ06 | XR08X | JZ10 | JZ13 |

| Cobalt Content (%) | 6 | 8 | 12 | 13 |

| WC Particle Size (μm) | 2-3 | 1-2 | 2-3 | 2-3 |

| Density (g/cm³) | 14.95 | 14.78 | 14.5 | 14.15 |

| Hardness (HRA) | 90.1 | 91.4 | 88.5 | 87.5 |

| Crosswise Tensile Strength (MPa) | 3,150 | 3,800 | 340 | 340 |

| Application Range | Applicable to the powder metallurgy dies with iron base, copper base and cemented carbide, female dies and core rod. | Applicable to the powder metallurgy dies with iron base, copper base and cemented carbide, female dies and core rod. | Having high strength and good wear resistance; applicable to the irregular concave dies pressed and made of iron powder and cooper powder. | |

| Designations | XR141 | XR203 | XR12U |

| Cobalt Content (%) | 15 | 20 | 12 |

| WC Particle Size (μm) | 2-3 | 3-6 | ≤0.5 |

| Density (g/cm³) | 13.9 | 13.55 | 14.1 |

| Hardness (HRA) | 88.2 | 84 | 92.5 |

| Crosswise Tensile Strength (MPa) | 3,300 | 2,700 | 3,800 |

| Application Range | Having higher strength and better wear resistance; Applicable to the concave dies with complex shapes and concave dies made of iron powder and copper powder with bigger pressure. | Having good tenacity; Applicable to metals stamping dies. | Applicable to NdFeBpowder metallurgy dies, other high pressure pressing dies, round female dies and core rod. |

| Specifications | Example | Note | |||||

| Outer Diameter (mm) | Tolerance (mm) | Inner Diameter (mm) | Tolerance (mm) | Height (mm) | Tolerance (mm) | ||

| Y********* | 100.5 | 1.5-2.0 | 100.5 | -2.0-1.5 | 60 | 1.0 | Blank |

| Y********* | 100.5 | 0.5 | 100.5 | -0.5 | 60 | -0.5 | Roughly Grinded |

Note: Both tungsten carbide blanks and roughly grinded powder metallurgy dies are available.

Scan QR to Read

Links:https://globefindpro.com/products/74543.html

Links:https://globefindpro.com/products/74543.html

Recommended Products

-

Stamping Dies

Stamping Dies

-

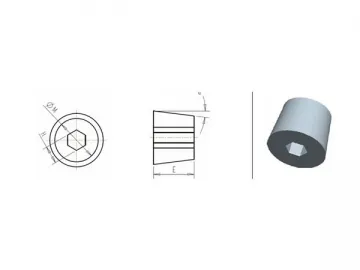

Tungsten Carbide Blanks (for Cold Heading Dies)

Tungsten Carbide Blanks (for Cold Heading Dies)

-

Metal Matrix Composite (Aluminum Clad Steel Sheet and Plate)

Metal Matrix Composite (Aluminum Clad Steel Sheet and Plate)

-

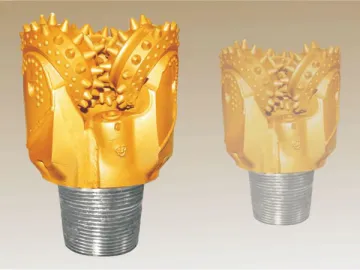

Tricone Bits

Tricone Bits

-

Artemis Plus Indoor Rental LED Display

Artemis Plus Indoor Rental LED Display

-

Tungsten Carbide Blanks (Carbide Hob Blanks)

Tungsten Carbide Blanks (Carbide Hob Blanks)

-

Metal Matrix Composite (Aluminum Clad Stainless Steel)

Metal Matrix Composite (Aluminum Clad Stainless Steel)

-

SQ Series DTH Hammer Bits

SQ Series DTH Hammer Bits

-

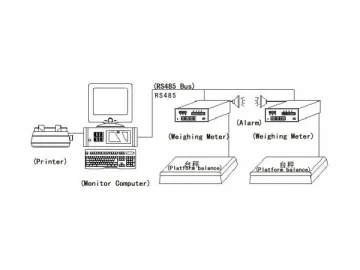

Computer Controlled Additive Dosing and Weighing System

Computer Controlled Additive Dosing and Weighing System

-

Dosing Machine

Dosing Machine

-

Metal Matrix Composite (Babbitt Metal)

Metal Matrix Composite (Babbitt Metal)

-

Aluminum Brazing Sheet

Aluminum Brazing Sheet